With the variety of cable ties emerging on the market, how can you select the most suitable one? The 2024 Latest Cable Ties Selection Guide will provide detailed suggestions on selecting the proper cable ties based on the type, material, and size. This guide aims to help you choose the most suitable cable ties according to your specific needs.

1. Understand the Use of Cable Ties

Before purchasing cable ties, it’s essential to understand their purpose. Different applications have varying requirements for cable ties, so knowing the intended use is the first step in selecting the proper cable ties. Here are some common applications and their requirements:

- Cable Management: Used to organize and secure light cable bundles, typically in home and office settings. light cable ties can handle it well.

- Industrial Use: Used to bundle pipes, hoses, or other industrial equipment, it requires higher strength and durability.

- Outdoor Use: Suitable for gardens, camping, or other outdoor activities, weather resistance, and UV resistance are required.

- High-Temperature Applications: For use in car engine compartments or some heat dissipation equipment, requiring good heat resistance or heat stability.

- Low-Temperature Applications: For example, in cold storage or cold regions, it is required that the zip ties maintain flexibility and strength at low temperatures.

- Special Applications: such as requiring reusable ties, cable ties with labels for identification, or different colored cable ties for classification and organization.

2. Select the Type of Cable Ties

Based on the purpose of the cable ties, you can determine whether you need nylon cable ties with special features.

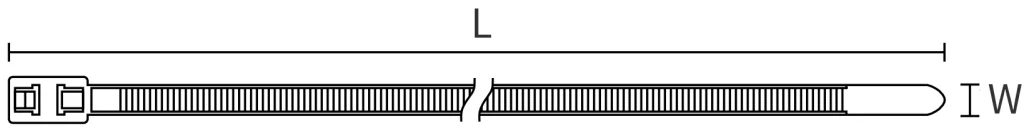

Reusable Cable Ties

These releasable cable ties can be opened and re-fastened, making them ideal for situations that require frequent adjustments.

Cable Tag Tie

Also known as identification cable ties and zip tie tags. They are perfect for situations that require identification, such as cable management. Cable tie manufacturers will customize logos or other markings on these ties, and you can also write directly on the labels for easy identification.

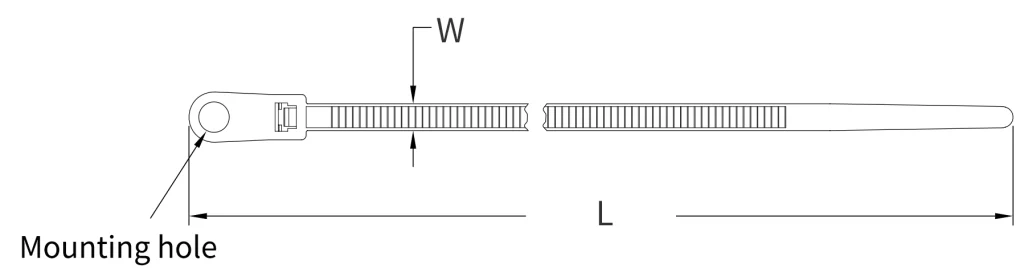

Screw Mount Cable Ties

This kind of cable tie has a hole in the head to cooperate with a screw, to fix the bundled harness in a specific position. They can be fixed to walls, equipment, or other surfaces, making them ideal for cable bundling and mounting.

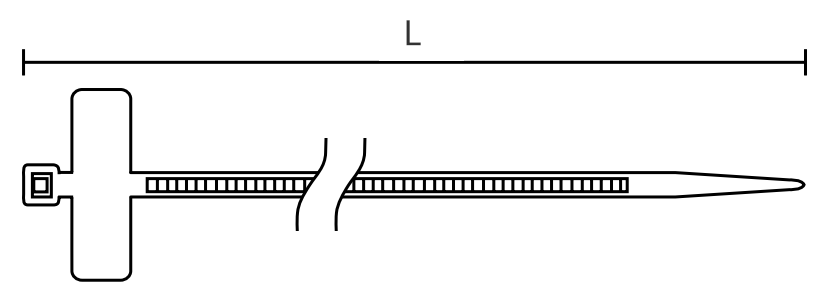

Double-Loop Cable Ties

As the name suggests, there are two pawls in the head, allowing you to bundle two separate cable groups with a single tie.

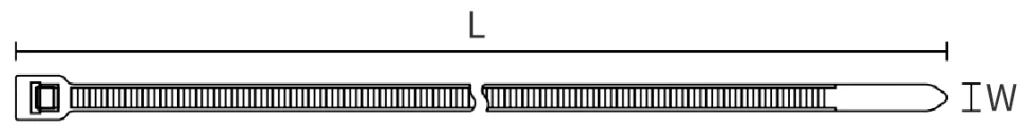

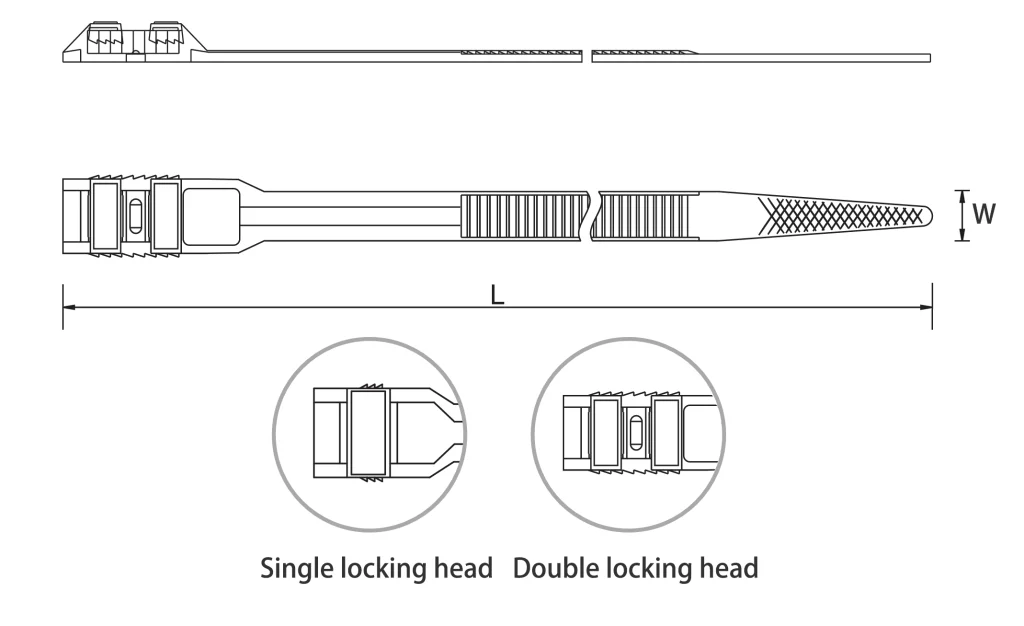

Low Profile Zip Ties

Available in single-lock and double-lock varieties, these ties have a low-profile head design. The teeth of the tie face outward, with the smooth side against the bundled items, as shown in the illustration. This design better protects the surface of the items, preventing abrasion and damage.

Zip Tie Handcuffs

Also known as police cable ties, these are designed similarly to handcuffs and are typically used for security and restraint purposes. They can be quickly locked and are difficult to escape from.

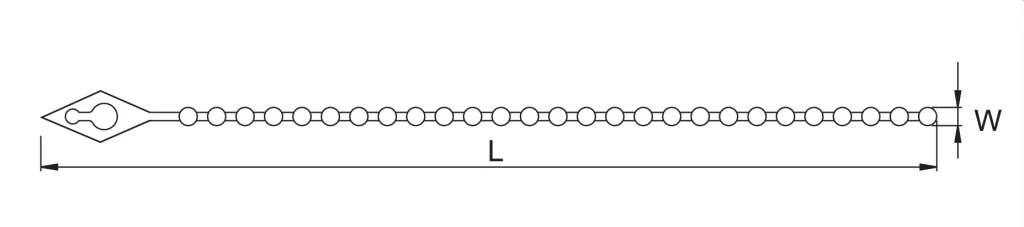

Beaded Cable Ties

These ties feature a beaded structure and can be reused. They are often used for bundling power cords or toy packaging.

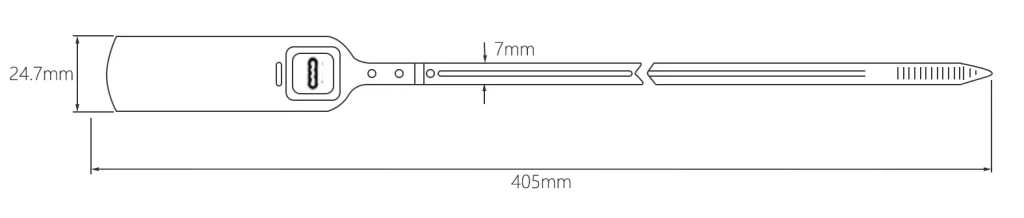

Plastic Seals

Also known as security seals, these are used where secure sealing is necessary, such as in cargo transportation and storage. They provide a secure lock, ensuring the integrity and safety of the goods.

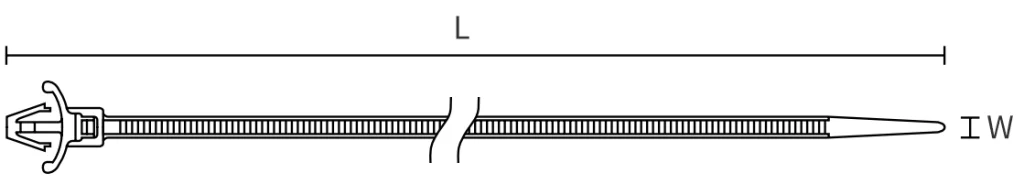

Push Mount Ties

Also known as fir tree ties, these are designed with a push mount head that can be easily inserted into pre-drilled holes. They are commonly used in automotive applications.

Low-Profile Cable Ties

Designed specifically for children’s play areas, these ties are used to secure soft barriers, mesh guards, and other safety equipment. They are designed with rounded edges to ensure they do not harm children during use. The design also takes into account durability and aesthetics. For more details, refer to the article “What are Low-Profile Cable Ties“

Colored Cable Ties

Used for classification and identification, different colored cable ties can help manage and distinguish items more effectively.

By selecting the proper type of cable tie for your specific needs, you can ensure optimal performance and efficiency in your application.

3. Explore the Material of Cable Ties

Choosing the right material for cable ties is equally crucial. In the article “Cable Ties: A Comprehensive Guide to Top 4 Materials,” we provide a detailed introduction to various materials used for nylon cable ties, such as PA12, PA6, PA66, and PA46, and explain the differences between them. Although they all belong to the nylon family, their material characteristics and costs vary significantly. For more specific information, please refer to the linked article.

4. Special Performance Required

Nylon cable ties are typically made from Nylon 66 (PA66), but depending on the specific application requirements, cable ties with special properties will be required to meet various complex environments. Here are the special cable ties and their unique features:

Heat-Resistant Cable Ties: Made from PA66HS, these can withstand high-temperature environments, typically enduring up to 150°C or even higher without deforming.

Cold Weather Cable Ties: Made from low-temperature PA66, these can endure extreme cold, down to -40°C, while retaining their flexibility and strength.

UV-Resistant Cable Ties: These ties resist damage from ultraviolet light, enhancing their durability and weather resistance for outdoor use.

Flame-Retardant Cable Ties: With a flame-retardant rating of UL94-V0, these offer higher flame resistance compared to standard nylon cable ties with a UL94-V2 rating. If you’re not familiar with the UL94 flame retardant ratings, you can refer to the article “UL94 Flammability: A Clear Guide for Cable Ties.”

5. Choose the Suitable Size of Cable Ties

After determining the type and material of the cable ties, it’s important to consider the cable tie sizes to ensure effectiveness and reliability in use. Here are some key size factors and recommendations.

Length:

Choosing the length of the cable ties is selecting the appropriate bundle diameter. The longer the cable tie, the larger the bundle diameter it can handle, as mentioned in the article “Choosing Right Cable Tie Sizes in 3 Steps: A Simple Guide.” Select the length based on the diameter of the objects being bundled. Specific parameters can be referenced in the standard nylon cable tie sizes chart.

Suggestion: Ensure that the length of the cable tie is sufficient to wrap around the item and leave a margin so that the cable tie can be securely fixed. Although two cable ties can also be connected, their performance will greatly decrease, as mentioned in the article “How to Connect Zip Ties to Make Longer“.

Width:

The tensile strength of cable ties varies with their width. Detailed standards for the tensile strength of different widths are provided in the article “Zip Tie Tensile Strength Standard and 4 Steps-Testing Methods.” Choose the appropriate width based on the required tensile strength. Wider cable ties offer higher strength.

Choosing the proper size of cable ties ensures their effective use in various applications. By selecting a suitable size, you can enhance efficiency and performance in your work and ensure the reliability of your bundled items.

Cable Ties Selection Guide

Through this comprehensive cable ties selection guide, we have detailed how to choose the proper cable ties based on their purpose, type, material, special features, and size.

We hope this guide provides valuable information to help you make informed decisions when purchasing cable ties. If you have any further questions or need more advice, please feel free to contact us!