One Step Ahead

Why We Are The Best

We pride ourselves on being industry leaders in the cable ties business. With our years of experience, we understand the ins and outs of this industry, ensuring that we provide our customers with the most durable, reliable, and high-quality cable ties. We stay ahead of the curve by constantly innovating and improving our products, keeping up with the latest technological advancements to give you the best.

360 Cable Ties Solutions

Explore What We Are Doing Better

In our commitment to excellence, we continuously strive to improve and enhance our processes, products, and services. This journey of improvement is not just about being better; it’s about exploring innovative ways to deliver exceptional results. We believe in not only meeting but exceeding the expectations of our clients, partners, and stakeholders.

Commitment to Improvement

Technological Innovations

People Development

Sustainability and Ethics

Learn All About Our Catalogue

Meet The Products

Automotive Cable Ties

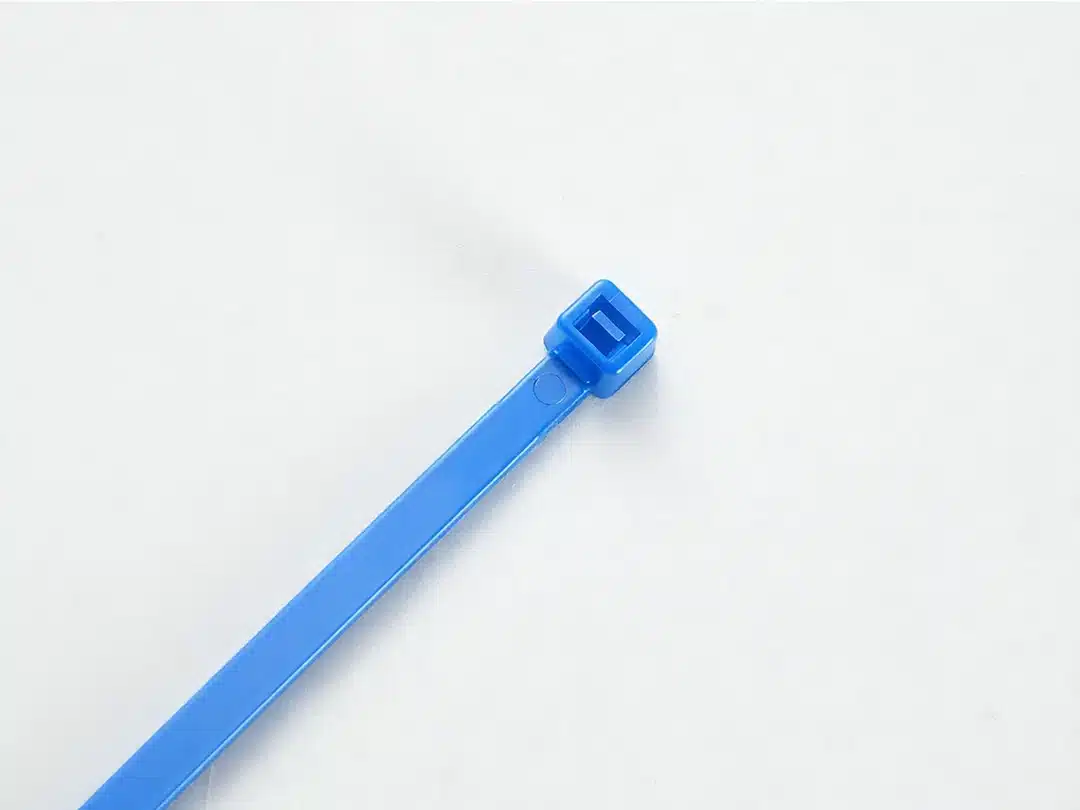

Nylon Cable Ties

Stainless Steel Cable Ties

three steps to success

We Will Help You Every Step Of The Way

From initial inquiry to final delivery, we’re committed to guiding and supporting you through every step of your journey with us.

01

learning about all your Needs

We start by understanding your needs, goals, and the challenges you are facing.

02

Align you with the optimal planning

We tailor a plan with products and services based on your needs.

03

Fight for Execution

We execute the plan efficiently, offering ongoing support for assured success.

we will assist you in any issue and conflict

Our team is prepared to assist in overcoming any difficulties or disputes you might encounter.

What People Say About Us

Client Testimonials

We have lots of experience

Case Studies

Cable Ties on German Site Fencing

On construction sites, cable ties are a common tool for temporary fixing. Fences need to be moved as work progresses. Warning signs may change from day to day. Walkways may also be adjusted in stages…

7 Practical Cable Tie Tips You’ll Actually Use

When people think about cable ties, the first things that come to mind are usually bundling wires or tying up packages. But cable ties can

Cable Ties at China’s Most Beautiful Bookstore Entrance

Cable ties are easy to miss at the entrance of Zhongshuge in Zibo—often called China’s “most beautiful bookstore”—but they solve a very practical problem. We noticed a single white cable tie linking…

How Cable Ties Help Keep a BMW Service Bay Organized

In a professional BMW dealership workshop, cable ties are everywhere. Neatly routed cables, well-organized hoses, and tidy work bays often depend on this simple tool. Cable ties help bundle air hoses…

Cable Ties Applications Inside BMW Motorcycles

When looking inside a BMW motorcycle—such as during maintenance or routine inspection—it is easy to notice nylon cable ties used throughout the bike’s interior. They

ETFE vs PFA Cable Ties: A Practical Selection Guide(170°C vs 260°C)

When buyers look for fluoropolymer cable ties, they often run into a confusing detail: one supplier lists a working temperature around 150–170°C, while another claims

6 Creative DIY Uses of Cable Ties by Makers

For many DIY makers, cable ties are not just tools for organising wires. They are more like a universal helper. When something needs to be temporarily fixed, quickly connected, or loosely assembled for…

Why Colored Cable Ties Are Used in Poultry Farming

In poultry farms, it is not unusual to see chickens wearing small pieces of colored cable ties on their legs. To people outside the industry,