Zip Tie Tensile Strength Standard and 4 Steps-Testing Methods

Every cable tie manufacturer should be intimately familiar with zip tie tensile strength standards and tests. After all, as a commonly used bundling tool, the efficacy and safety of a zip tie hinge directly on its quality. While there are many performance metrics to consider, tensile strength stands out as both foundational and critical. In this article, Nike Plastic will walk you through the standards and testing methods for nylon zip tie tensile strength measured in Newton.

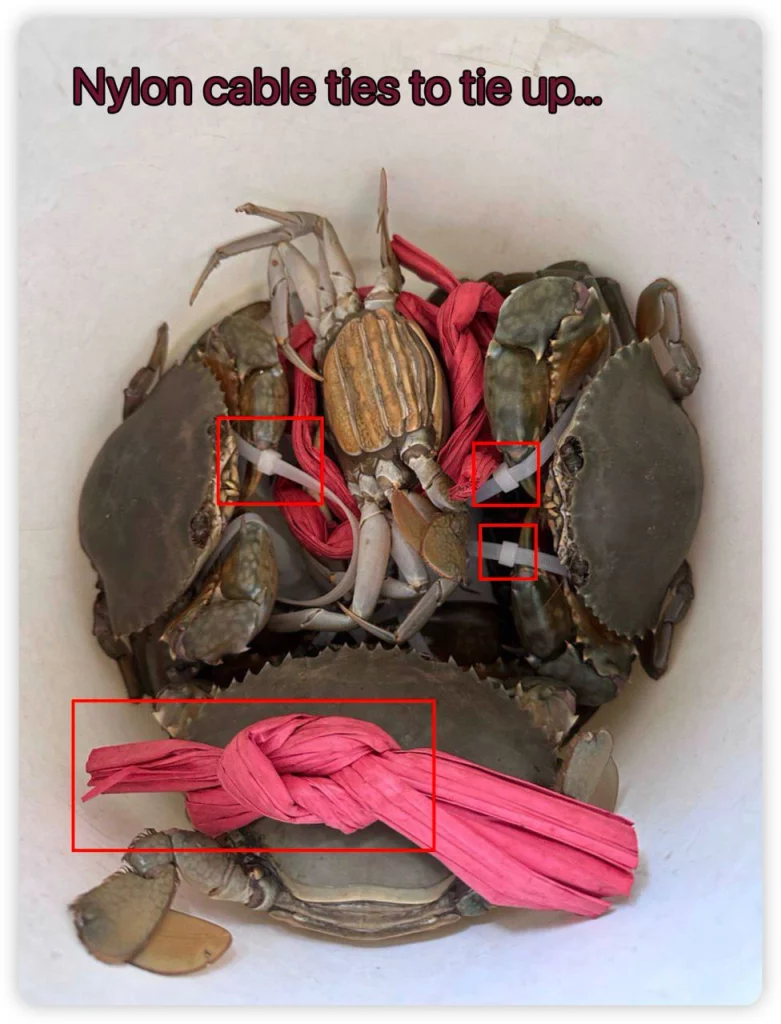

2 Harnessing the Power of Nylon Cable Ties to Secure Hairy Crabs and Blue Crabs

Nylon cable ties to tie up hairy crabs and blue crabs? Why? Many people may want to know the answer because these are two things, one is cable ties, an industrial product; the other is hairy crabs and blue crabs, which are food products. So, how do these two different products come together? Let’s take […]

China’s No.1 Fair: The 134th Canton Fair

The Canton Fair, formally known as The China Import and Export Fair, began its journey in the spring of 1957. Ever since, this grand event, held biannually in the spring and autumn at the Pazhou International Convention and Exhibition Center in Guangzhou, China, has been a staple of China’s trade scene. As China’s oldest, largest, and premier trade exhibition, it’s renowned as “China’s No.1 Fair”.

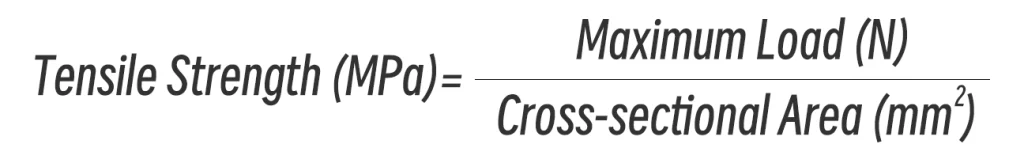

1 Min Quick Guide: Cable Tie Tensile Strength

“What is the Cable Tie Tensile Strength in N/mm²?” Have you ever pondered over the question? While in our daily business, we typically use Newtons (N) or kilograms (kg) to describe the minimum tensile strength of nylon cable ties, the unit N/mm² (or MPa) is more accurate in depicting the tensile strength of its material. Now, let’s take just one minute to delve into the tensile strength of a nylon cable tie in N/mm².

7 Innovative Uses of Cable Ties

In our daily lives, are nylon cable ties merely tools for securing and bundling? Actually, these zip ties have numerous creative uses that may surprise you. Their versatility goes far beyond simple binding. At NIKE Plastics, we’ve compiled a list of seven innovative and practical uses for nylon cable ties:

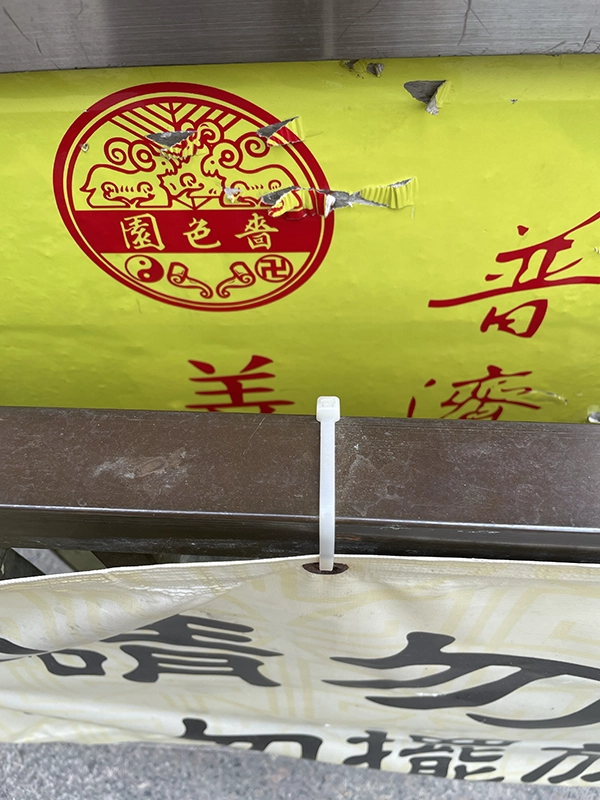

6 Brilliant Uses of Nylon Cable Ties at the Wong Tai Sin Temple in Hong Kong

Actual Use Cases of Nylon Cable Ties at the Wong Tai Sin Temple in Hong Kong In August 2023, we received a real-life application case of nylon cable ties at the Wong Tai Sin Temple in Hong Kong from Tom. From the photos, we can see that the paper, for waterproofing and sun protection reasons, […]

Cable Ties in the Hong Kong Thriving Construction Industry: 3 Exclusive Photos

The Application of Nylon Cable Ties in the Hong Kong Construction Industry I. Introduction II. Types of nylon cable ties The types of nylon cable ties can be broadly categorized based on materials and use into the following main groups: Auto Cable Ties, Cold Weather Cable Ties, Double Loop Cable Ties, Flame-retardant Cable Ties, Heat […]

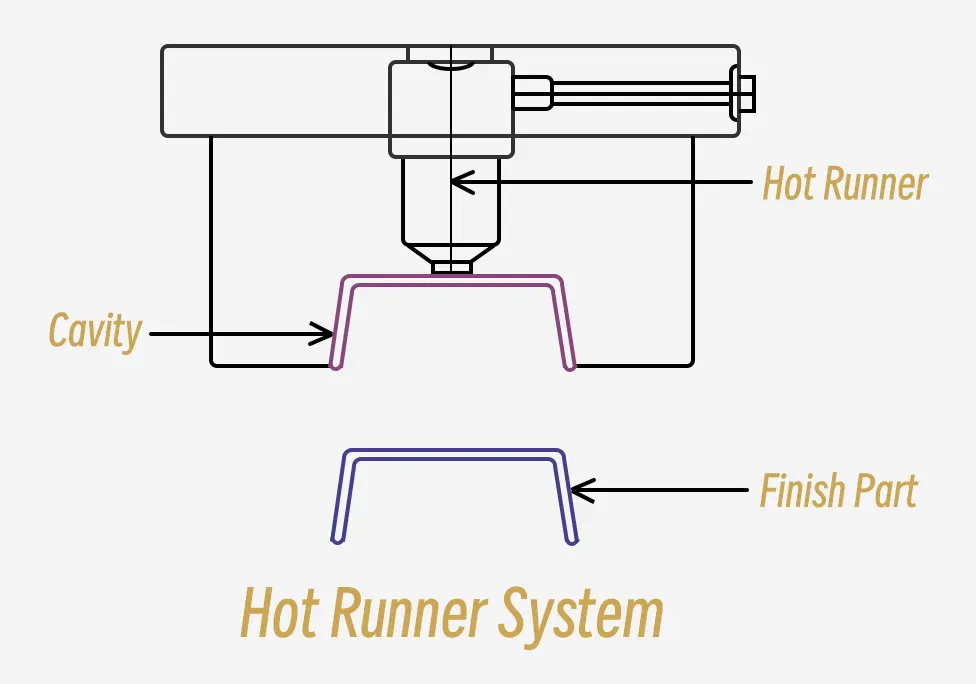

Hot Runners vs Cold Runners in Cable Tie Production: 4 Key Differences

In the injection molding process of nylon cable ties, the pivotal decision that cable tie manufacturers grapple with is whether to employ a cold runner or a hot runner system. This choice steers the production efficiency and directly correlates with the product quality and the eventual cost incurred. Therefore, making a wise choice is paramount. Today, we at NIKE PLASTIC…

Why Nylon Cable Ties Turn Brittle in Biting Cold

Why nylon cable ties turn brittle in biting cold? Especially under cold conditions or cold winters. Is a common concern in industrial applications and everyday scenarios. Let’s dive into why this happens.

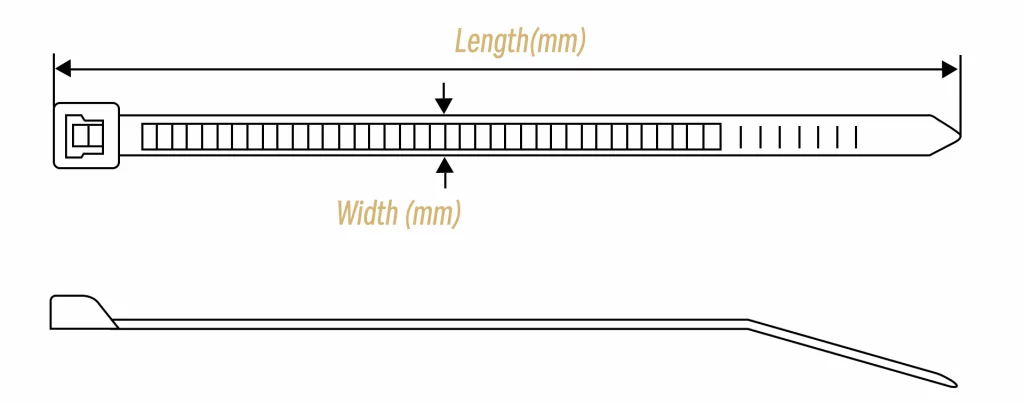

Choosing Right Cable Tie Sizes in 3 Steps: A Simple Guide

Choosing the right size for nylon cable ties is a critical step in ensuring the safety and effectiveness of cable management. This decision involves careful consideration of some key factors. In this guide, we’ll provide a concise overview to help you select the appropriate cable tie sizes for your specific application.