Why Cable Ties Break in Winter and How to Solve It? As winter sets in, some cable tie manufacturers face a recurring complaint raised by customers: “Why are the cable ties so brittle and prone to breaking in winter?” This problem, common in cold climates, often leads to a question: Why do these normally durable ties fail in low temperatures? There are, in fact, several factors that contribute to this brittleness. In this article, we will explore the reasons and offer some practical solutions to address such challenges.

Why do Cable Ties Break in Winter?

1. Characteristics of Cable Tie Material

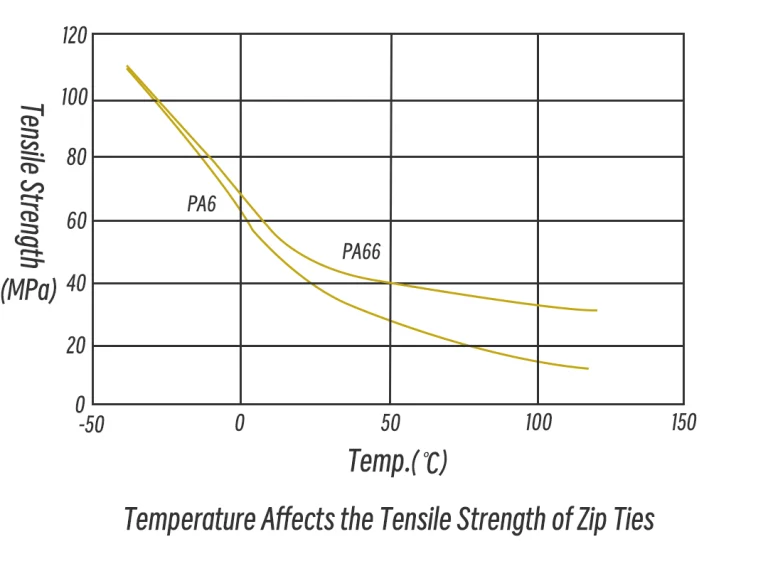

In exploring why cable ties are prone to breaking in winter, a critical focus is on the material characteristics of cable ties. Cable ties, often made from Nylon 66 (PA66), are known for their flexibility and strength in normal temperatures. However, in cold winter conditions, they become more prone to breakage due to changes in their material properties, closely linked to molecular structure and movement:

1.1 Slowed Molecular Motion: In cold temperatures, molecules in nylon move slower. Consequently, when force is applied to the cable tie, it is harder for the material to evenly distribute the force. This results in increased interaction forces between molecules that don’t spread out as effectively.

1.2 Deformation and Stress Concentration: The friction among molecular chains increases, and their mobility decreases in cold temperatures. This reduced deformability leads to stress concentration at specific points, increasing the risk of breakage.

1.3 Occurrence of Breakage: Once internal stress reaches a certain threshold, the long polymer chains in nylon can break. These breaks start as tiny cracks, which, under continuous stress concentration, quickly grow, ultimately leading to the failure of the cable tie.

2. Effect of Humidity on Cable Ties

Humidity plays a significant role in the performance of cable ties. As detailed in the article “Water Absorption in Cable Ties“, nylon inherently has a degree of water absorption. This hygroscopic nature means that in humid environments, they can absorb moisture. Conversely, it also indicates their susceptibility to losing water.

In winter or dry conditions, the lower atmospheric humidity can reduce the moisture content of cable ties. When nylon loses moisture, the sliding ability between its molecular chains decreases. Under external forces or stretching, the intensified interactions between these less mobile molecular chains make them more prone to breakage. This vulnerability becomes especially evident in winter when dryer conditions prevail.

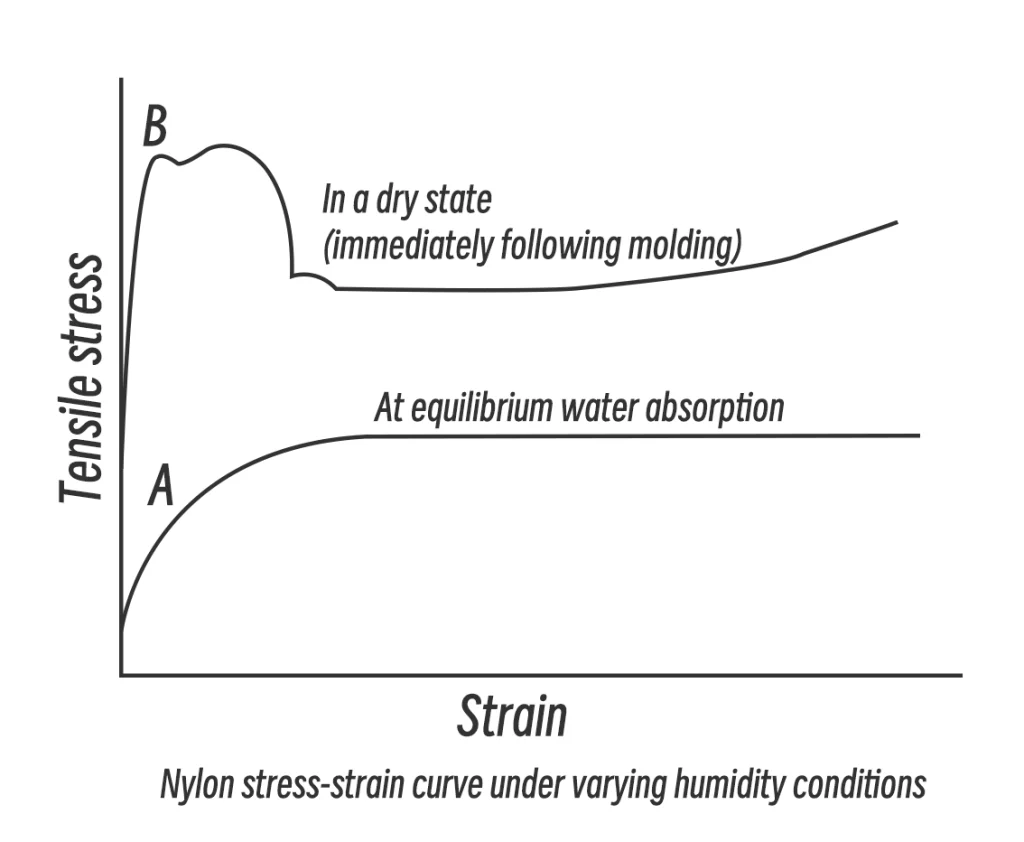

To better understand this phenomenon, let’s consider the graph below. It shows the stress-strain curves of nylon material under varying humidity conditions. Curve ‘A’ represents the material after reaching equilibrium with water absorption, demonstrating its enhanced flexibility and greater elongation before breaking. Curve ‘B’ shows the material in a dry state, right after molding, where it exhibits higher stress at lower strain levels, indicating a greater likelihood of breakage when dry. This visual representation corroborates that nylon cable ties are more supple and less likely to snap when they contain moisture, whereas drier conditions contribute to their fragility.

3. Material Aging

Material aging, although not accelerated by cold temperatures, becomes more pronounced in cable ties during winter. Low temperatures can further diminish the elasticity of already-aged nylon material. This implies that even minor external forces can lead to the breakage of cable ties in colder environments. The weakened state of the material, combined with the challenges of low temperatures, makes older nylon cable ties particularly vulnerable to snapping. For a detailed description of how cable ties undergo aging and its effects, you can refer to the article “Why Your Nylon Cable Ties Turn Yellow: Causes & Fixes“

4. Quality and Production Process of Cable Ties

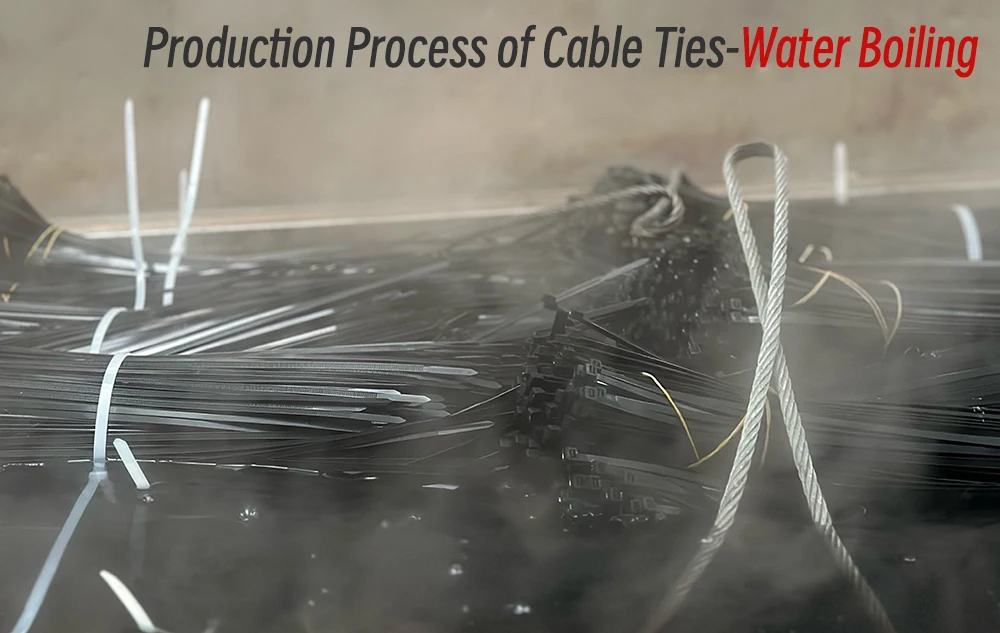

Moreover, beyond the standard cable tie manufacturing process, Nike Plastics incorporates a unique ‘water boiling’ step. This additional process, although increasing labor and material costs, significantly improves the toughness of the cable ties. This treatment, applied after the injection molding process, provides extra fortification to the nylon cable ties, ensuring superior durability in extremely cold conditions. These meticulous adjustments in the production process ensure that the cable ties remain safe and reliable for use during the colder seasons. This is also one of the reasons why our standard cable ties can withstand temperatures up to-25℃, or even lower.

Solutions to Prevent Cable Ties from Breaking in Winter

- Pre-warming with Hot Water: Before using cable ties, immerse them in warm water for about half an hour. This temporary measure can enhance the material’s flexibility and reduce its brittleness in cold environments. While this method may be a bit cumbersome, it is proven effective.

- Slow Application: When using standard cable ties in temperatures below 0°C, avoid tightening them quickly. Instead, apply tension slowly and evenly to decrease the likelihood of stress concentration and breakage.

- Opt for Thicker and Stronger Cable Ties: In cold environments, it’s advisable to use cable ties that are wider or thicker and have higher tensile strength. These ties can better withstand the pressure generated during fastening, reducing the chance of breaking.

- Store in a Warm Environment: Keep the cable ties in a warm place, like a heated room or workshop, to maintain their flexibility before use.

- Use Low-Temperature Cable Ties: For environments below -20°C with high requirements for low-temperature resistance, it’s recommended to use low-temperature cable ties which are specifically designed for cold conditions, capable of withstanding temperatures down to -40°C.

Ensuring Reliability in Winter Conditions

In conclusion, the brittleness of cable ties in winter can be attributed to various factors, including material characteristics, environmental conditions, aging, and cable tie quality. By adopting measures such as pre-warming in hot water, selecting thicker ties, and ensuring proper storage, users can effectively mitigate these issues. For extreme cold conditions, specialized cold weather cable ties are highly recommended.