The water absorption in cable ties is a crucial aspect for cable tie manufacturers and users, as it significantly impacts the cable tie’s performance and application range. Today, let’s delve into what cable tie water absorption is, the absorption rates for different materials, and how this property affects performance and injection molding.

What is Nylon (Polyamide)?

Nylon, often known as polyamide (PA), is a high-performance material known for its resistance to high temperatures, wear, and chemicals. However, a notable drawback of polyamide is its relatively high water absorption.

What is Water Absorption?

Water absorption, or moisture absorption, is the ability of a polymer to absorb moisture from the environment, typically expressed as a percentage of the water’s weight compared to the original weight of the material. This factor is crucial in various fields, particularly in polymers, as absorbed water acts as a plasticizer. It lowers the plastic’s strength, a reversible effect. However, it can also cause irreversible degradation of the polymer structure.

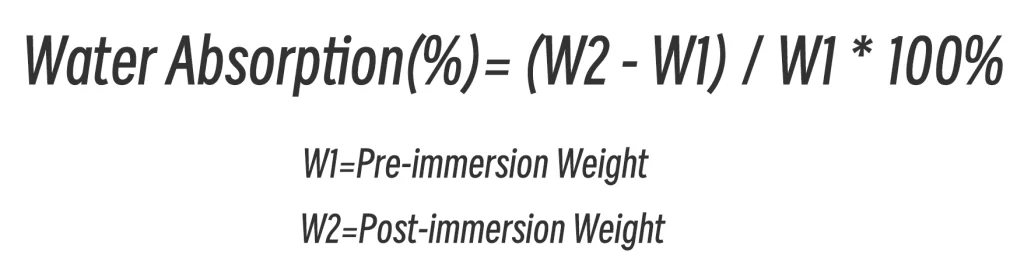

How to Calculate the Water Absorption Rate of Cable Ties?

The water absorption rate of cable ties is calculated as the percentage increase in the weight of a plastic sample. Generally, it can be calculated by the following formula:

What are the Effects of Water Absorption in Cable Ties?

This should be the most concerning issue for everyone, and some known effects include:

Appearance:

After absorbing water, the cable ties exhibit certain effects, such as changes in appearance and quality. For instance, cable ties used in humid environments may slightly expand in size and decrease in density due to their high water absorption rate. Although its changes in size are minimal, it did.

Mechanical Properties:

Elasticity: After absorbing water, nylon typically becomes more flexible due to the moisture acting as a plasticizer.

Tensile Strength: Water absorption may cause a decrease in tensile strength as it weakens the material’s internal cohesion.

Impact Strength: The absorption of moisture can significantly enhance the impact strength, making the material more resilient against shocks.

Electrical Properties:

Regarding electrical properties, water absorption can reduce the electrical insulation capabilities of nylon, as moisture increases conductivity. Therefore, the water absorption of nylon is a key consideration in applications requiring high electrical insulation.

What are the Factors that Affect the Water Absorption in Cable Ties?

The properties of the material itself: Different types of polymers or plastics have different abilities to absorb water. For example, plastics of polyamide (nylon) and polyester types typically absorb more water.

Material processing methods: Different processing methods can affect the microstructure of materials, thereby altering their water absorption. For example, products produced by injection molding and extrusion processing may have different water absorption properties.

Environmental factors, including temperature, humidity, water quality, etc., may affect the water absorption rate of materials. Generally speaking, the higher the temperature and humidity, the more water absorption plastic will have.

The type and proportion of fillers in the material: for example, reinforcing fillers, mineral fillers, or other additives may affect the water absorption of the material.

Material morphology: For some polymers, such as polyamide, their water absorption is affected by the degree of crystallinity of the material. Water absorption is lower for those with high crystallinity.

How to Measure the Water Absorption Rate of Plastics?

The most widely used standards are ASTM D570 and ISO 62, which measure the weight change of the sample before and after water immersion.

The ASTM D570 – 98(2018) method involves:

- Thoroughly drying the sample until its weight stabilizes.

- Recording the dry weight (W1).

- Immersing the sample in deionized water at 23°C.

- After intervals (like 24 or 48 hours), remove the sample, wipe off surface moisture, and record its weight (W2).

- Repeating step 4 until no significant weight change occurs.

ISO 62:2008 method involves:

- Recording pre-immersion dimensions and weight (W1).

- Soaking the sample under specified conditions.

- After intervals (like 24 or 96 hours), remove surface moisture and record its weight (W2).

The water absorption rate is calculated as Water Absorption (%) = (W2 – W1) / W1 * 100%, where W1 is the pre-immersion weight and W2 is the post-immersion weight.

What are the Water Absorption Rates for Different Types of Nylon?

| Polymer | Min Value (% weight) | Max Value (% weight) |

| PA 11, Flexible | 0.8 | 1.6 |

| PA 12,Flexible | 0.9 | 1.9 |

| PA46 – Polyamide 46 | 1.3 | 3.7 |

| PA 6 – Polyamide 6 | 1.6 | 1.9 |

| PA 66- Polyamide 6/6 | 1 | 3 |

Summary

Understanding water absorption in cable ties is very crucial. As a leading cable tie manufacturer, we rigorously monitor various parameters in production and quality control, including the water absorption in cable ties. We precisely adjust product characteristics based on end-user applications and requirements, ensuring optimal performance under diverse conditions.