Have you ever wondered why nylon cable ties turn yellow? Does this yellowing indicate a quality issue? And is it still working after yellowing? Today, NIKE Plastic will discuss the primary reasons for this discoloration and offer some effective prevention measures.

Material of Nylon Cable Ties

Nylon cable ties, often called cable ties or zip ties, are made from a synthetic polymer known as polyamide. Their durability and certain elasticity have made them widely used in various applications. However, even though nylon is a high-performance polymer, it is still susceptible to oxidation and aging.

Reasons for Yellowing of Nylon Cable Tie

Ultraviolet Radiation

Exposure to ultraviolet radiation triggers a chemical reaction in the ties, altering the molecular structure of the nylon. This process, called “photooxidation,” not only turns the ties yellow but also reduces their strength, making them more brittle.

Thermal Oxidation

Under high-temperature conditions, the nylon material may undergo thermal oxidation. This reaction forms “yellowing agents, ” giving the plastic ties a yellow hue. The speed of thermal oxidation is proportional to the temperature: the higher the temperature, the faster it occurs.

Impurities

This primarily pertains to certain additives used in the production process and other impurities. These impurities can also absorb light, turning yellow, and may accelerate the degradation process. Insufficient additives or fillers might also cause discoloration during processing or storage.

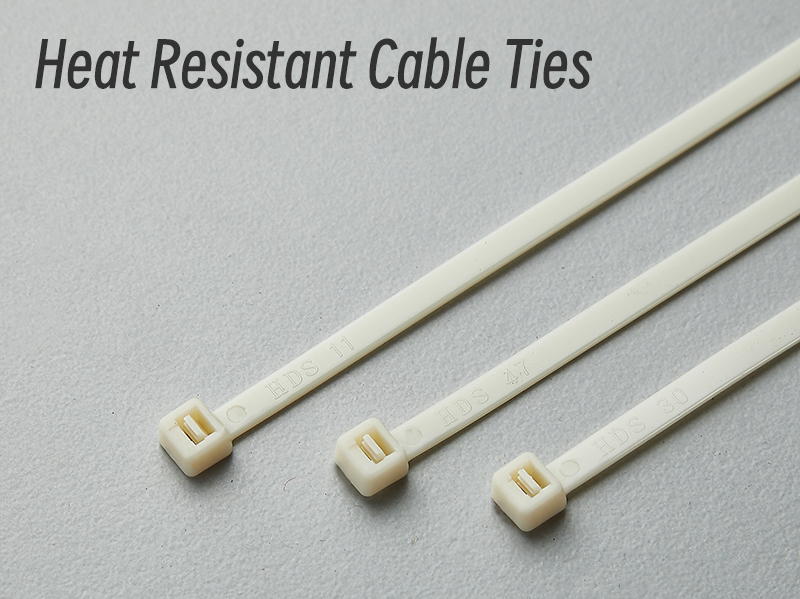

Special Material of Zip Ties

Different types of cable ties, such as nylon 6 zip ties, nylon 66 zip ties, high-temperature-resistant ties, cold-resistant ties, and flame-retardant ties, display varying colors due to their unique raw materials. For instance, nylon 6 cable ties are the whitest, while nylon 66 ties have a slight yellow tint and are more transparent. The difference is subtle. However, heat resistant cable ties and flame-retardant cable ties, show a faint yellow known as “natural color” – it’s the inherent color of the material.

Conclusion

In summary, the yellowing of nylon cable ties is typically due to the degradation of polymer chains. This degradation might occur under the combined effects of oxygen and ultraviolet radiation—known as photooxidation—or in high-temperature conditions, termed thermal oxidation. During these processes, a “yellowing agent” forms, turning the nylon ties yellow.

Additionally, impurities within the ties might absorb light, manifesting as a yellow hue and potentially accelerating degradation. Insufficient additives or fillers might also lead to discoloration during processing or storage. Other factors causing discoloration include thermal interactions, exposure to pollutants, mechanical interactions, hydrolysis, and chemical interactions.

Therefore, the yellowing or discoloration of cable ties doesn’t necessarily indicate poor quality or product issues. In fact, it’s a natural phenomenon due to environmental factors and the chemical properties of the ties themselves. Nevertheless, it can’t be denied that ties that turn yellow (excluding those naturally faint yellow) may see a decline in mechanical properties, becoming brittle and losing toughness. This is because yellowing is often accompanied by the degradation of polymer chains, implying a weakening of the tie’s structure.

How to Prevent Yellowing of Nylon Cable Ties

Nylon cable ties, while robust and versatile, can succumb to the elements over time. Yellowing, in particular, can be a telltale sign of degradation, but with proper precautions, you can ensure a longer lifespan for these ties. Here are some proactive measures to take:

- Proper Storage: Keeping your nylon cable ties in a cool, dry place is crucial. Exposure to moisture or high temperatures can accelerate the yellowing process. If you’re storing them for an extended period, consider using airtight containers or resealable plastic bags to protect them from environmental contaminants.

- Limit UV Exposure: Direct sunlight is one of the main culprits behind the yellowing of nylon products. Where possible, use and store your ties in shaded or indoor areas. If they must be used outdoors, try to position them in places where they’ll be shielded from direct sunlight most of the time.

- Opt for UV-Resistant Ties: If your application demands outdoor use, consider investing in cable ties that are specifically designed to resist UV radiation. They might be a bit more expensive initially, but the added durability will often justify the cost in the long run.

- Regular Inspection: Periodically check your stored cable ties. If you start to notice any discoloration, it might be an indication that the storage conditions aren’t ideal. Adjusting the environment early can save the rest of your ties from degradation.

- Use Additives: Some manufacturers offer cable ties treated with anti-yellowing additives or stabilizers. These compounds can help maintain the color and structural integrity of the ties over prolonged periods.

- Rotate Stock: If you buy cable ties in bulk, ensure that you’re using the older stock first. This ensures that none sit around long enough to start yellowing before they’re used.

While the discoloration may not always indicate a compromised quality, it’s essential to approach it with an informed perspective and prioritize appropriate storage and product selection.