On construction and electrical installation sites, cable ties are among the most commonly used accessories. They are commonly used for tying rebar, securing conduits, providing temporary support, and organizing wiring in distribution boxes. Compared with traditional iron wire, cable ties are faster and safer to use — no extra tools are needed to get a firm hold. Because they are easy to handle and low in cost, cable ties have gradually become an essential tool in both construction work and electrical installations.

Applications on Construction Sites

During the construction phase, cable tie is mainly used for the temporary fixing of rebar and pipelines, as shown in the photo below. When tying rebar, workers often use cable ties instead of iron wire — the process is faster and eliminates the need for cutting and twisting, greatly improving overall efficiency. In addition, the smooth cut of a cable tie leaves no sharp edges, reducing the risk of hand injuries for workers. For more details on proper trimming, see the article “How to Cut Cable Ties.”

Cable ties are also used to position conduits or secure safety nets during embedded piping and formwork installation. Although these bindings are temporary, they help keep materials in place and make subsequent work much easier.

Applications in Electrical Installation

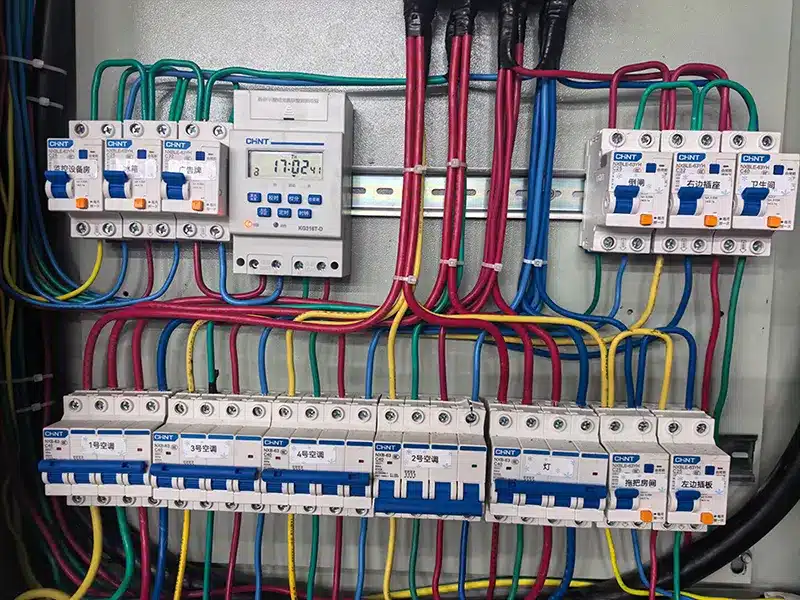

In the electrical installation phase, the most common use of cable ties is for cable organization. Inside a distribution box, cables often come in different colors and sizes. Without proper bundling, they can easily become tangled and messy. Using plastic ties to group and secure the cables keeps the wiring neat and also makes future maintenance easier.

Electrical environments place higher demands on materials, so flame-retardant or high-temperature-resistant cable ties are usually preferred. Even when exposed to heat or electrical arcs, these types of ties help reduce safety risks. Compared with metal fasteners, nylon ties are lightweight, flexible, and do not damage cable insulation, making them a popular choice in electrical installation work.

The Practical Value of Nylon Cable Ties on Construction Sites

On construction sites, nylon cable ties are everywhere. They are widely used for several key reasons:

- First, they’re easy to use. Cable ties are small, portable, and ready to use anytime. No extra tools are needed, and a secure hold can be achieved in just a few seconds.

- Second, they’re safe. Unlike iron wire, once the tie’s cut end is trimmed flat, it won’t scratch workers’ hands or damage cables and pipelines.

- Third, they’re versatile. With a wide range of sizes and types, cable zip ties can be used for rebar, pipes, or electrical wiring. Whether for temporary reinforcement, safety net installation, or cable management inside distribution boxes, cable ties play a part in nearly every stage of construction.

- Lastly, they’re cost-effective. Cable zip ties are inexpensive, used in large quantities, and easy to restock without adding much to project costs.

So, whether it’s tying rebar, securing conduits, or organizing wires in an electrical panel, the tool workers reach for most often is a simple nylon cable tie. It’s quick, convenient, and practical — a small item that construction work simply can’t do without.