In construction machinery, cable ties are a common tool for organizing wires. They may look small and simple, but they play an important role.

Take the boom lift we photographed as an example. This kind of equipment has a complex structure with many wires going in different directions. It also works outdoors for long hours, facing sunlight, wind, and strong vibrations. In such conditions, keeping the wires neat and secure is not easy. That’s where the nylon cable tie comes in. They are one of the easiest and most useful ways to hold wires firmly in place.

In this article, we share real photos of the XCMG XGS series boom lift. From the guardrails on the control platform to the hydraulic system wiring, you can see how cable ties are used to fix and organize cables in real working conditions. These small ties help make the equipment safer, cleaner, and easier to maintain.

1. Where Are Cable Ties Used? — A Look at the XCMG XGS Boom Lift

From our real-world photos of the XCMG boom lift, it’s clear that cable ties are used in many key spots to secure and organize wires and hoses.

For example, on the control platform guardrails, there’s a layer of black corrugated tubing wrapped around the frame. This tubing helps protect operators from bumps and also prevents the metal from getting too hot in the sun. The tubing is held in place using white nylon ties spaced evenly along the rail. The ties make installation easy and keep everything neat and functional.

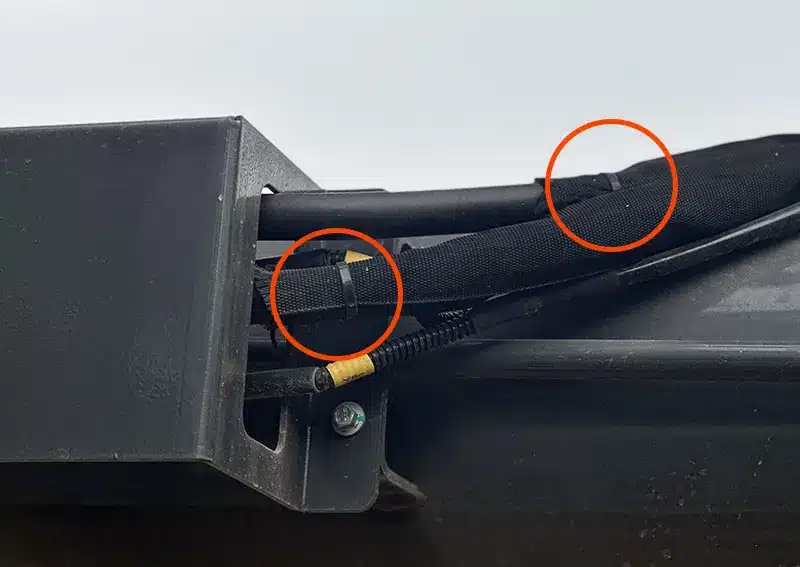

Near the bottom of the machine—around the wheels and boom sections—there are many cables and hydraulic hoses that need to be routed together. These are first covered with protective sleeves, then secured with cable ties at intervals to prevent movement or contact with other parts of the machine.

In some cases, nylon ties are used together with braided mesh sleeves. This method keeps the cables in place while still allowing some flexibility, which is helpful during maintenance or future adjustments.

From the top of the boom to the base of the chassis, and from controllers to actuators, wherever there are wires or tubes to manage, you’ll likely find cable ties doing the job.

2. What Do Cable Ties Do on Boom Lifts?

On complex machines like boom lifts, cable ties do much more than just “hold things together.” They help ensure safe and stable operation, especially in challenging outdoor environments. Here’s how:

Keeping Cables Organized and Safe

Boom lifts have a dense network of sensors, controllers, and actuators. Cable tie helps fasten these cables securely to trays or brackets, reducing the risk of friction, pulling, or breakage caused by vibrations. This prevents signal issues or control failures and forms a basic layer of protection for reliable operation.

Keeping Space Clear and Accessible

Neatly tied cables not only look better but also prevent wires from blocking access panels or operator controls. During repairs or inspections, a well-organized cable layout makes it easier and faster for technicians to locate and solve problems.

Handling Harsh Outdoor Conditions

Construction machines work in tough environments—heat, rain, oil, and more. High-quality PA66 cable ties are built to handle it all, offering resistance to high and low temperatures (from -40°C to +85°C or more), oil, UV rays, and even some level of flame resistance (UL94 V-2). This makes them a solid choice for long-term outdoor use.

Reducing Vibration Fatigue

Constant movement during driving or operation can cause cables and hoses to wear out, loosen, or break over time. Cable tie helps reduce that vibration fatigue by keeping everything stable, extending the lifespan of wires and connectors.

Supporting Professional Maintenance

Good cable management makes the entire system look more professional and easier to upgrade or repair. When cables are grouped, labeled, and color-coded properly, cable ties often serve as the base that holds everything together.

3. How to Select Industrial Zip Ties That Work?

In heavy-duty environments like construction machinery, not just any zip tie will do. It’s not just about “tying something up”—it’s about choosing the right material, size, and performance to match the job. Here are the key factors to consider when selecting industrial zip ties:

For Reliable Performance: Nylon 66 or Heat-Resistant Nylon Ties

Nylon 66 cable ties are the preferred option for industrial use thanks to their strong resistance to heat, tension, and chemicals. For areas exposed to high temperatures, we recommend heat-resistant cable ties rated from -40°C to +120°C. These offer better durability and safety under tough conditions.

Get the Right Cable Tie Sizes

Cable ties commonly come in widths like 2.5mm, 3.6mm, 4.8mm, and 7.6mm. Choose the appropriate width and length based on the number and size of the items you’re bundling. A tie that’s too thin or too short may break or fail to hold securely.

Prioritize UV-Resistant Cable Ties for Outdoor Use

Construction machines often operate outdoors, so UV-resistant cable ties are essential. Keep in mind: not all black zip ties are UV-resistant. For more on this, see our related article: “Are UV-Resistant Cable Ties Only Available in Black?”

Choose the Right Locking Style

- Standard cable ties: Best for most fixed, long-term applications.

- Releasable cable ties: Ideal for temporary setups or situations where wires need to be adjusted or removed. They’re reusable and flexible.

Stick with Trusted Brands: Quality can vary a lot across the market. Choose reliable brands like Huada, HellermannTyton, or KSS. Always share your specific application needs with your supplier before placing an order. Poor-quality zip ties can snap, slip, or become brittle in cold conditions, leading to both operational issues and safety risks.

4. How to Maintain Cable Ties on Heavy Equipment

Even though cable ties are low-cost consumables, their condition can still affect wire safety, especially on heavy-duty equipment used outdoors for long periods. High temperatures, sun exposure, wind, dust, and oil can all accelerate aging, making nylon ties brittle or causing them to break.

Here’s how to keep them in good condition:

1. Inspect Regularly: Check your zip ties during routine maintenance, or at least every 6 to 12 months. Look for signs of aging, such as fading (black turning white, white turning yellow), brittleness, or looseness. In key areas, gently bend the ties to see if they crack or snap. If they feel fragile, it’s time to replace them.

2. Replace When Necessary: If a tie shows signs of wear or damage, replace it immediately. Always use a tie of the same or better grade—wider ties usually offer stronger support. When removing old cable ties, be careful not to cut or damage the wires beneath.

3. Cut with Care: Use a cable tie gun or diagonal pliers to flush the tie with the surface. Avoid leaving sharp ends, which can scratch nearby components or injure someone during maintenance.

5. Every Cable Tie Matters

Cable ties may not be the core component, but they are an essential detail. On boom lifts—where safety is critical—neat and secure wiring helps reduce risks and makes maintenance easier.

Though low in cost, cable ties carry real responsibility. That’s what gives them their value in heavy-duty equipment.