When buying cable ties, one of the most frequently asked questions is: What are the differences between nylon 6 and nylon 66 cable ties? Although we briefly touched upon their differences in our article ‘Cable Ties: A Comprehensive Guide to Top 4 Materials‘, today, we’ve decided to conduct a high-temp testing of nylon 6 and nylon 66 cable ties. This test aims to reveal the differences in tensile strength under high temperatures between these two materials, assessing whether they can maintain their performance stability when exposed to elevated temperatures, which is one of the biggest differences between the two materials.

Max Working Temperature of Nylon 6 and Nylon 66 Cable Ties

Cable ties, are generally made from PA (Polyamide), for example, PA6 and PA6/6. Theoretically, these two materials can withstand a maximum working temperature of up to 85°C. But can they be used at such high temperatures? Will it affect the tensile strength? Can the temperature be higher? Let’s find out in a “test” for truth!

Test Preparation

The sample preparation is as follows:

- PA6: 15 pieces of 4.8x300mm cable ties

- PA66: 15 pieces of 4.8x300mm cable ties

Test Start

1. Room Temperature Tensile Test

Test initial tensile strength with 5 cable ties of each PA6 and PA66.

Record the tensile strength of each material.

2. High-Temperature Treatment

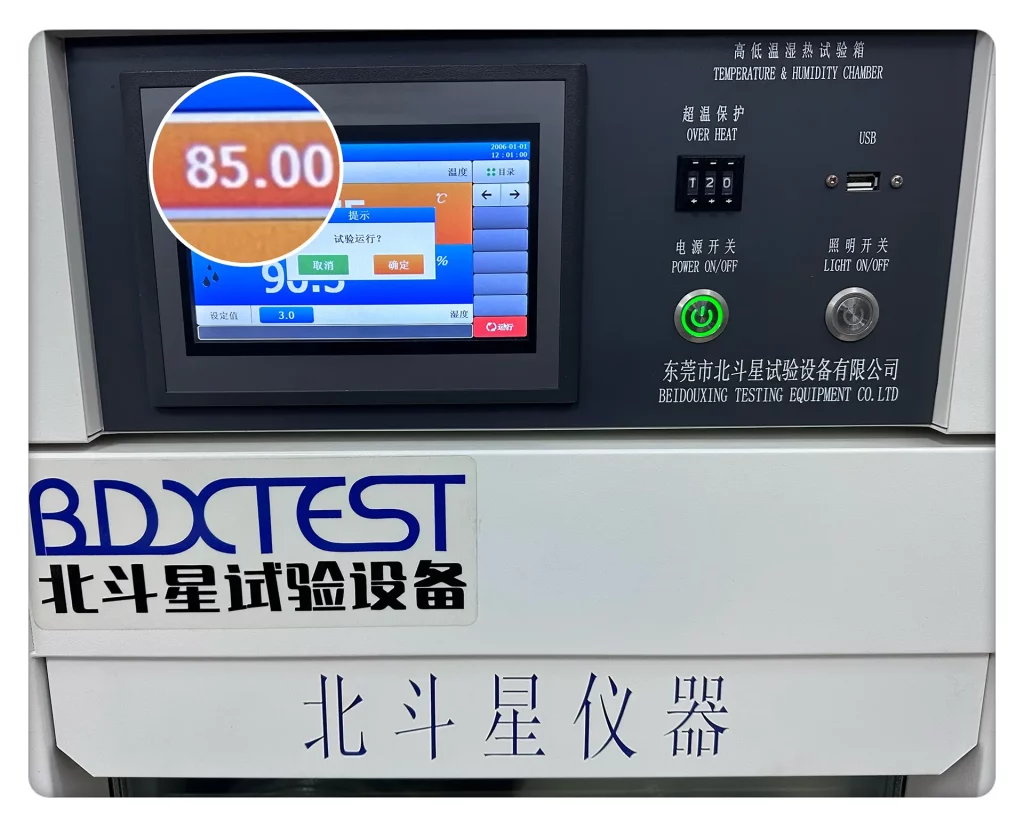

Place 10 cable ties of each PA6 and PA66 in a high-temperature box at 85°C for 2 hours.

3. Post-High-Temperature Tensile Test

After 2 hours at 85°C, test the tensile strength of 5 cable ties from each material.

Record the results.

4. Continued Testing at 100°C

Increase temperature to 100°C and maintain for 2 hours for the remaining cable ties.

5. Final Tensile Testing

Perform tensile strength testing after exposure to 100°C.

Record the final data.

6. Data Results

Note: Samples were tested in groups of 5. Tensile strength change is calculated as the average of each group.

Data Analysis

Both materials showed a decrease in tensile strength at 85°C and 100°C, with nylon 6 cable ties showing a slightly greater decrease than nylon 66 cable ties.

The change in tensile strength of the cable ties is calculated using the formula:

(Initial Tensile Strength1 – Post-High-Temperature Tensile Strength) / Initial Tensile Strength × 100%.

- Observations at 85°C: Both nylon 6 and nylon 66 cable ties exhibited a decrease in tensile strength when subjected to a temperature of 85°C. Notably, the decrease in tensile strength for nylon 6 cable ties was slightly more pronounced than that for nylon 66 cable ties.

- Observations at 100°C: Similar trends were observed at 100°C, with both materials showing a reduction in tensile strength. Again, nylon 6 cable ties showed a marginally greater decline compared to nylon 66 cable ties.

Overall Analysis

The percentage change in tensile strength was slightly higher for nylon 6 cable ties than for nylon 66 cable ties, indicating that nylon 66 might possess better thermal stability under high temperatures. This conclusion is drawn from the fact that nylon 66’s decrease in tensile strength is slightly lower than that of nylon 6 cable ties at both tested temperatures, suggesting better heat resistance.

However, it’s important to note that these findings are based on short-term testing data and are meant for reference only. They do not fully reflect the long-term performance of the materials under extreme conditions. For applications requiring prolonged exposure to high temperatures, using heat resistant cable ties is recommended to ensure reliability in such environments.

Conclusion

Although this test lasted only four hours, it still reveals notable differences in temperature resistance between nylon 6 and nylon 66 cable ties. It is important to emphasize that this test serves merely as a preliminary reference. The quality of cable ties can vary significantly among different cable tie manufacturers, which can affect aspects such as the material quality and the tensile strength of the cable tie. Given the limited conditions of our test, the results should be considered as a guide only.

For more on the thermal properties of PA6 and PA66 materials, including details like glass transition and melting temperatures, stay tuned for our upcoming articles. We’ll be exploring more on the thermal performance of cable ties.