Practical Use of Cable Ties in Coffee Machines

Cable ties in Coffee machines show the versatile use of this small tool in modern appliances. As coffee becomes more and more popular, coffee machines also become common in daily life. The…

The Practical Application of Cable Ties in Hong Kong Residential Buildings

The practical application of cable ties in Hong Kong residential buildings is the theme of our article today. As we all know, the real estate of Hong Kong is at a premium. Compared to residents on…

What are Hose Clamps and Where are They Applied

What are hose clamps and where are they applied? That’s what we’re focusing on today. While metal cable ties are quite common, stainless steel hose clamps—a special type of these cable ties—may…

Are UV-Resistant Cable Ties Only Available in Black?

Are UV-resistant cable ties only available in black? This is a common misconception, especially in outdoor settings where UV-resistant cable ties are typically black. This is due to the traditional…

Is Tensile Strength of Cable Ties Important

Is tensile strength of cable ties important? Cable ties are everywhere in both our work and daily lives. You might have used them to organize computer cables, or seen workers use them to secure…

HUADA at The 135th Canton Fair

The 135th Canton Fair started on April 15, 2024! Known as one of the biggest trade shows around, the China Import and Export Fair has been a key spot for international trade since 1957. Every year…

A Comprehensive Guide to Metal Cable Ties

The guide to metal cable ties offers a comprehensive introduction to metal cable ties, assisting users to understand better and utilize this powerful and practical tool. Renowned for their…

Test the Tensile Strength of Metal Zip Ties in 3 Effective Steps

The Tensile strength of metal zip ties is a crucial parameter for assessing their performance and suitability, ensuring their safety and efficiency in industrial and construction applications.

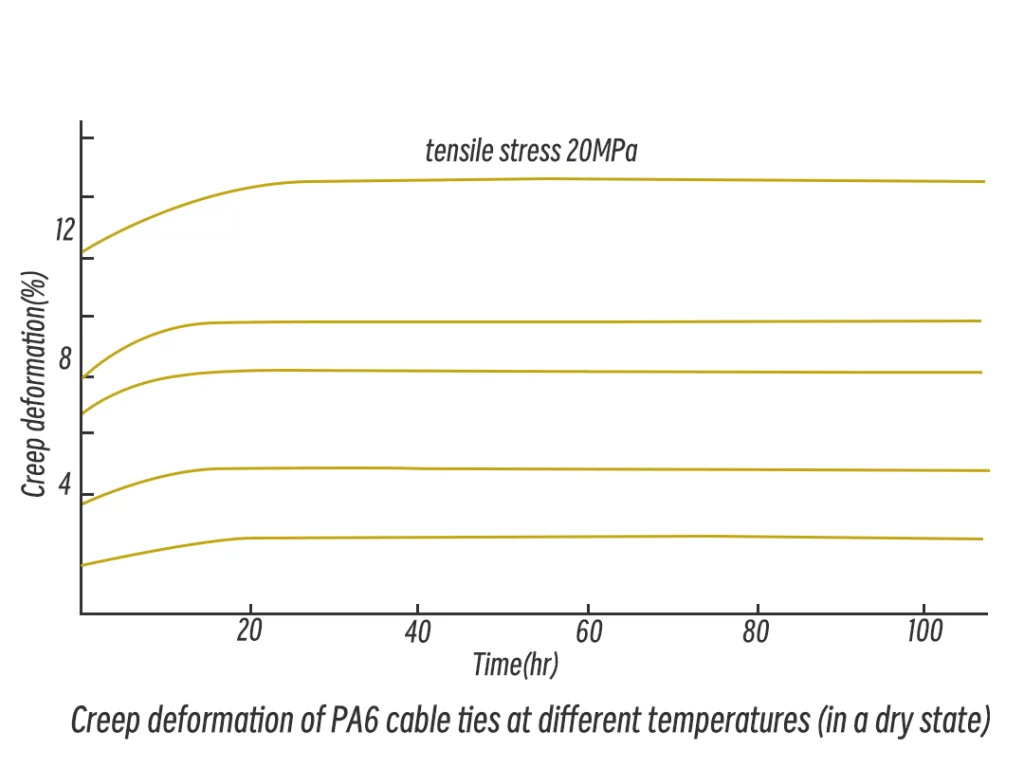

Exploring the Creep of Cable Ties

The creep of cable ties is a phenomenon where the cable ties undergo a permanent deformation over time under sustained mechanical stress. Understanding this property is crucial for the use of polymer materials like nylon…

How to Use Stainless Steel Cable Ties Exploring 2 Effective Methods

How to Use Stainless Steel Cable Ties? Generally, there are two methods. The first involves manually tightening the tie and then using scissors to trim off the excess. The second method requires a specialized stainless steel cable tie tool, which provides a more precise and secure application.