In the UK, stainless steel hose clamps are a very common fixing method in urban streets and public transport infrastructure. They are frequently seen at connections between signposts, bus stop facilities, and various equipment brackets mounted on poles or columns. This type of stainless steel fixing, based on a threaded screw mechanism, is widely used for on-site installation.

Unlike self-locking cable ties, stainless steel hose clamps work through a bolt-and-thread structure that allows adjustable tightening. Installers can gradually apply clamping force as needed, and the clamp can be loosened or re-adjusted later during maintenance. While the structure itself is simple, its continued use across UK infrastructure reflects a practical and efficient working logic developed over many years.

To understand why hose clamps are so widely adopted, it is not enough to look only at the product itself. It is more useful to consider the environments they serve—locations where adjustment, repositioning, and ongoing maintenance are often required, and where fixings must remain adaptable rather than permanently locked in place.

What Is a Stainless Steel Hose Clamp?

A stainless steel hose clamp is an adjustable fixing device that uses a screw and threaded band to apply controlled circumferential clamping force. By tightening the screw, the clamp gradually and precisely tightens around the object being secured, allowing installers to apply exactly the amount of force required. When adjustment or removal is needed, the screw can simply be loosened, making the clamp fully reusable rather than disposable.

For outdoor use in the UK, stainless steel hose clamps are most commonly made from 304 or 316 stainless steel. These grades offer a well-balanced combination of corrosion resistance, mechanical strength, and long-term stability, allowing the clamp to withstand damp air, rain, and prolonged outdoor exposure. Compared with carbon steel or galvanized clamps, stainless steel hose clamps are far less likely to seize, weaken, or lose functionality due to corrosion over time.

This combination of an adjustable structure and a durable stainless steel material is what makes stainless steel hose clamps particularly suitable as a maintainable fixing solution. They provide strong, reliable clamping during installation, while still allowing components to be loosened, repositioned, or replaced later—without cutting or replacing the fixing itself.

Typical Applications of Stainless Steel Hose Clamps in the UK

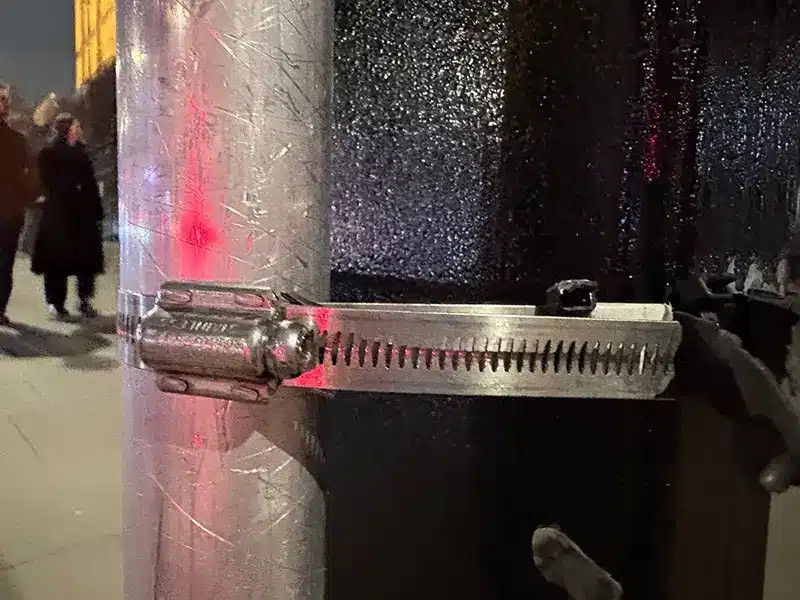

In the UK, stainless steel hose clamps are most commonly used at the connection between signposts and sign panels. From on-site photos taken by Tom, it can be seen that sign panels are usually mounted against round poles using metal brackets, then secured in place by one or more hose clamps wrapped around the pole. This installation method relies entirely on the clamping force of the hose clamps and requires no drilling or welding on the pole itself, helping to protect the structure while also simplifying installation.

The way hose clamps are applied also shows a high degree of practical flexibility. For smaller signs or applications with limited load, a single clamp is often sufficient. For larger sign panels or longer mounting sections, multiple stainless steel hose clamps are installed in parallel. This parallel installation spreads the load without changing the basic structure and is a very common detail seen on UK streets.

At bus stops and other public transport facilities, the use of stainless steel hose clamps becomes even more varied. In addition to securing the main sign panels, hose clamps are often used to fix auxiliary information boards, equipment brackets, or small structural components. Based on on-site observation, these elements are rarely installed all at once. Instead, they are added, adjusted, or replaced over time as routes change and information is updated. In this context, hose clamps serve as an adjustable connection that can be easily re-tightened or repositioned when needed.

On infrastructure that has been in service for many years, visible signs of use—such as scratches or surface wear—can often be seen on the hose clamps. Even so, the threaded mechanism and clamping condition typically remain intact. This provides a clear indication of the long-term reliability of stainless steel hose clamps in outdoor UK environments.

Why Stainless Steel Hose Clamps Are Commonly Used Outdoors in the UK

In practical use, many fixing points in the UK roadside infrastructure and public transport facilities offer very limited working space. This is especially true at connections between sign backs, mounting brackets, and poles, where nearby walls, guardrails, or other structures may leave little room for tools or adjustment. In these locations, the way a fixing conforms to the structure and the space it requires during installation becomes critical.

In such situations, stainless steel hose clamps allow continuous tightening through their threaded screw mechanism. As the screw is tightened, the band closes evenly around the object and sits flush against the surface, leaving very little excess clearance once installed. The operation itself is also relatively straightforward in confined spaces.

By comparison, self-locking cable ties often retain a certain amount of curvature after locking, while Ear-Lokt stainless steel cable ties require folding and crimping, which demands more tool clearance. In tight installation areas where components sit close together, the hose clamp structure is often easier to handle and easier to install flush against the surface.

This advantage is not primarily about higher strength or durability, but about structural suitability. In space-limited outdoor installations, the geometry and tightening method of stainless steel hose clamps simply match the installation conditions better. This practical fit is one of the key reasons they are so commonly used across the UK outdoor infrastructure.

Conclusion

Overall, the widespread use of stainless steel hose clamps in UK outdoor environments is driven more by practicality in installation and maintenance than by any single performance advantage. Their adjustable structure, close-fitting clamping method, and ability to be loosened and re-tightened make them a highly practical fixing option for roadside infrastructure and public transport systems.

That said, hose clamps are not the only solution used outdoors in the UK. In locations where frequent adjustment is not required, Ear-Lokt stainless steel cable ties or self-locking stainless steel cable ties are also commonly seen. There is no simple hierarchy between these fixing methods. Instead, each structure is suited to different installation conditions and maintenance needs, which ultimately determines where it is used.