“What is the Cable Tie Tensile Strength in N/mm²?” Have you ever pondered over the question? This rarely-asked question was from one of my customers, and it led me to a deeper dive into the topic.

While in our daily business, we typically use Newtons (N) or kilograms (kg) to describe the minimum tensile strength of nylon cable ties, the unit N/mm² (or MPa) is more accurate in depicting the tensile strength of its material. Now, let’s take just one minute to delve into the tensile strength of a nylon cable tie in N/mm².

What is Tensile Strength

Tensile strength describes the ability of a material to resist breaking under tensile (stretching) stress. It’s usually defined as the maximum force that the material can bear per unit area, and it’s measured in N/mm² (MegaPascals or MPa).

Differences between units “N” and “N/mm²”(MPa)

In English, both “N or kg” and “N/mm²” can indeed be referred to as “tensile strength,” but their meaning is slightly different.

N: This typically refers to the maximum force that an object can withstand until it breaks. When discussing this, we often specify the units, such as N (Newtons) or kg (kilograms). In English, this can be termed a “tensile load.”

N/mm²(MPa): It is a metric indicating the maximum stretching stress a material can endure before breaking.

Simply put, while tensile force is an external force applied to an object, tensile strength is the internal resistance of the material against breaking.

Calculation for Cable Tie Tensile Strength

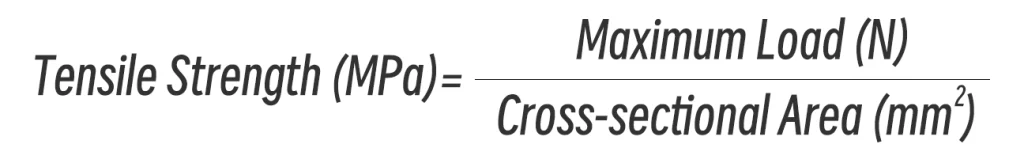

To derive the tensile strength of nylon cable ties, we use the following formula:

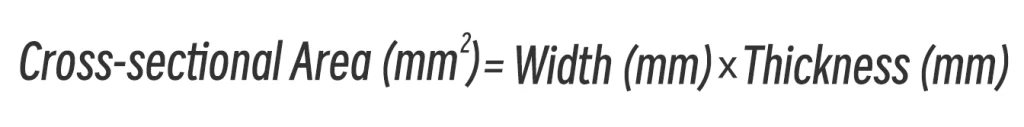

The cross-sectional area is obtained by multiplying the width and thickness of the cable tie:

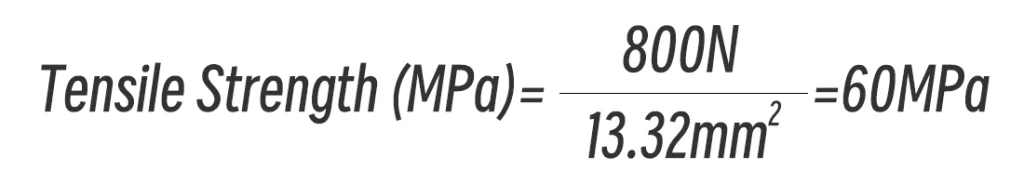

For example, the maximum load of a nylon tie before fracture is 800N, and its cross-sectional area (width x thickness) is 9mm x 1.48 mm = 13.32 mm ². Then its tensile strength should be:

Zip Tie Tensile Strength

Zip ties boast commendable tensile strength, making them a preferred choice in many vital applications. The tensile strength can vary among different cable-tie manufacturers and cable-tie brands.

Test method

The standard procedure for testing the tensile strength of nylon cable ties often adheres to the ASTM D638 guidelines. Here are the key steps and considerations:

Test Samples

The ASTM D638 standard mandates the use of standardized samples of specific shapes and sizes. This ensures consistent comparisons between different batches and materials.

Testing Equipment

Universal testing machines are used to steadily apply tension and accurately record force and displacement.

Test Procedure

The nylon cable tie is fixed between the clamps of the testing machine. The tie is then stretched until it breaks, with the machine recording the maximum force exerted before breakage.

Data Analysis

Results are typically presented as an average, often inclusive of the standard deviation to reflect the variability in results.

Conclusion

The cable tie tensile strength provides a precise benchmark that aids in scientifically selecting and recommending products. Both tensile strength and tensile force offer insights into the performance capabilities of cable ties, helping users make informed choices.

If you’d like to know more about the tensile strength of cable ties in various specifications, please feel free to reach out to us at Nike Plastics. We are available 24/7 to address your queries and concerns.