In industrial applications, zip tie sizes are more than just a matter of length—it directly affects tensile strength, bundle compatibility, and installation efficiency. A tie that is too short may fail to secure the object, while one that is too long or too thick may lead to unnecessary material cost.

Unlike in home use, industrial environments require zip tie dimensions to match project needs more closely than in home use—for safety and performance. Whether bundling cables in control cabinets, securing hoses on heavy machinery, or routing wires in tight confined spaces, choosing the right zip tie sizes ensures dependable performance, faster installation, and reduced maintenance risk.

This guide is designed to help purchasing teams, site engineers, and system integrators understand how to evaluate zip tie sizes properly—by considering not only length and width, but also thickness, bundle diameter, tensile strength, and application-specific constraints.

2. What Zip Tie Sizes Mean

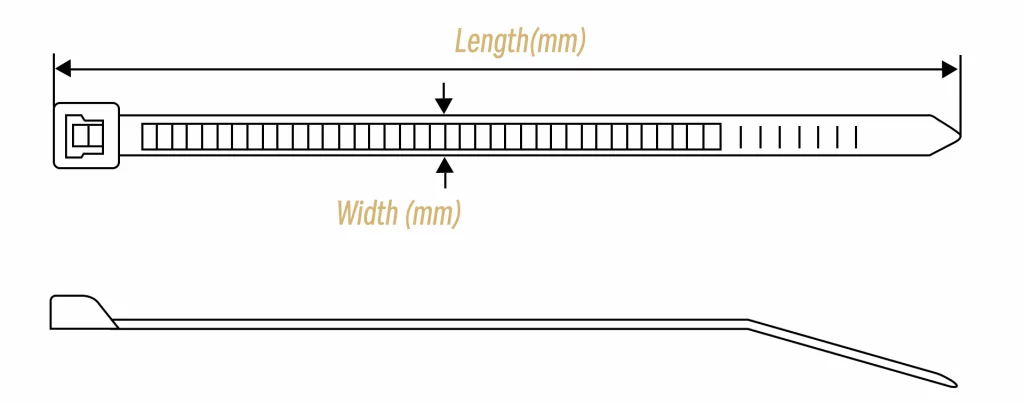

Zip tie sizes are typically defined by three key dimensions:

Length

This refers to the overall length of the tie, which determines the maximum bundle diameter it can secure.

In practical terms, this is calculated based on the effective length—the portion of the strap that can be wrapped and locked—rather than the total molded length. (See our article “Everything You Need to Know About Cable Tie Sizes” for reference.)

Width

Directly influences tensile strength and load-bearing capacity. Wider ties are generally stronger and suitable for heavier-duty applications.

Below are typical tensile strength ranges based on common zip tie widths (PA66 material):

- 2.5mm – 8kg

- 3.6mm – 18kg

- 4.8mm – 22kg

- 7.6mm – 55kg

- 9.0mm – 80kg

- 12mm – 120kg

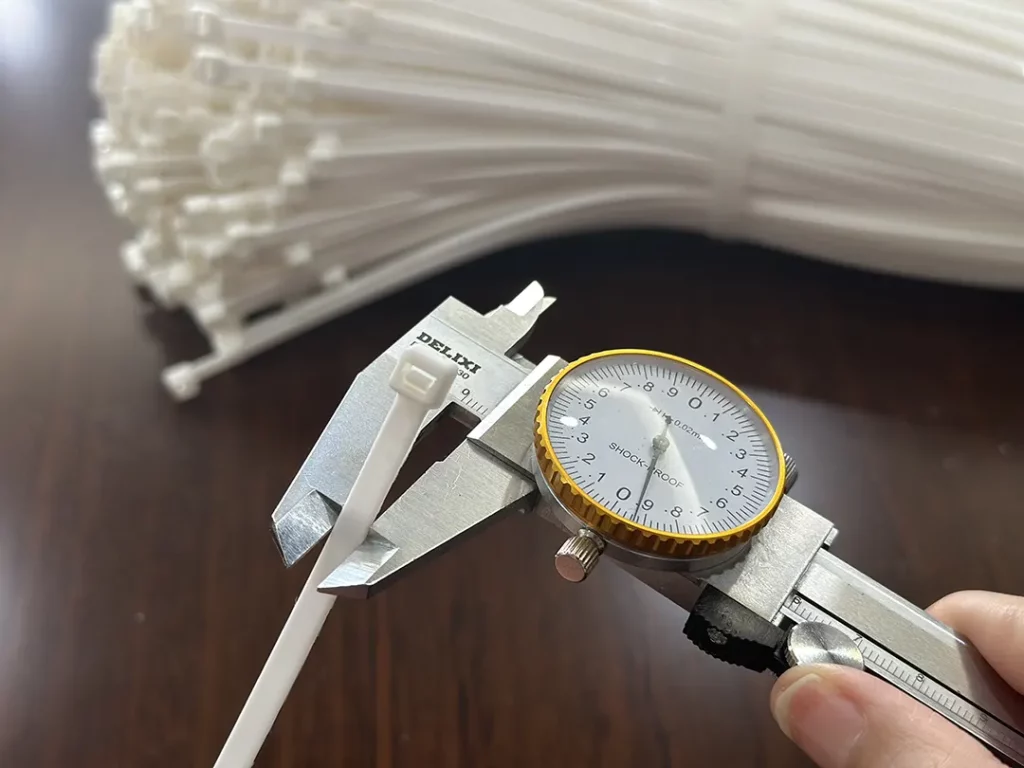

Thickness

Which is often overlooked, thickness plays a key role in both mechanical strength and cost. For the same width, a thicker zip tie will typically offer greater tensile strength and resistance to deformation.

However, thicker is not always better: once the tensile strength requirement is met, adding thickness usually only increases cost.

Take our 7.6*300mm zip tie as an example. We manufacture it in 1.4mm, 1.5mm, and 1.6mm thickness variants. While the 1.6mm version offers the highest tensile strength, the 1.4mm version already meets most application requirements—and does so more cost-effectively.

At Huada Plastic, we don’t blindly chase thickness. A reliable cable tie isn’t just about being heavier or bulkier—it’s about intelligent design and material control.

A capable factory ensures that even standard-thickness cable ties can consistently meet tensile strength requirements, based on real-world usage needs—not theoretical overengineering.

By understanding all three dimensions—length, width, and thickness—industrial buyers can select zip ties that are not only strong and reliable, but also optimized for performance, cost, and efficiency.

3. Zip Tie Size Chart

Choosing the right zip tie sizes depends on multiple factors: bundle diameter and required tensile strength. Below is a selection guide covering common industrial sizes:

| Zip Tie Sizes | Length | Width | Max.Bundle DIA.(mm) | Tensile Strengths | |

| Inch | mm | (mm) | lbs | ||

| Light Duty Cable Ties | 3 3/16” | 80 | 2.5 | 16 | 18 |

| 4‘’ | 100 | 2.5 | 22 | 18 | |

| 4 3/4” | 120 | 2.5 | 30 | 18 | |

| 6” | 150 | 2.5 | 35 | 18 | |

| 6 1/4” | 160 | 2.5 | 40 | 18 | |

| 8” | 200 | 2.5 | 50 | 18 | |

| Medium Duty Cable Ties | 4” | 100 | 3.6 | 22 | 40 |

| 4 3/4” | 120 | 3.6 | 30 | 40 | |

| 6” | 150 | 3.6 | 35 | 40 | |

| 7” | 180 | 3.6 | 42 | 40 | |

| 8” | 200 | 3.4 | 50 | 40 | |

| 10” | 250 | 3.4 | 65 | 40 | |

| 11 5/8” | 300 | 3.6 | 80 | 40 | |

| 14 1/2” | 370 | 3.5 | 102 | 40 | |

| 4 3/4” | 120 | 4.8 | 24 | 50 | |

| 6” | 150 | 4.8 | 35 | 50 | |

| 7” | 180 | 4.8 | 42 | 50 | |

| 8” | 200 | 4.8 | 50 | 50 | |

| 10” | 250 | 4.8 | 65 | 50 | |

| 11” | 280 | 4.8 | 70 | 50 | |

| 11 5/8” | 300 | 4.8 | 82 | 50 | |

| 13 3/4” | 350 | 4.8 | 90 | 50 | |

| 14” | 360 | 4.8 | 95 | 50 | |

| 15” | 370 | 4.8 | 102 | 50 | |

| 15 3/4” | 400 | 4.8 | 105 | 50 | |

| 17” | 430 | 4.8 | 115 | 50 | |

| 17 3/4” | 450 | 4.8 | 130 | 50 | |

| 19 11/16” | 500 | 4.8 | 150 | 50 | |

| 22 10/16” | 550 | 4.8 | 175 | 50 | |

| 6” | 600 | 4.8 | 33 | 50 | |

| 25 19⁄32” | 650 | 4.8 | 42 | 50 | |

| Heavy Duty Cable Ties | 10” | 250 | 7.6 | 63 | 120 |

| 11 5/8” | 300 | 7.6 | 82 | 120 | |

| 13 3/4” | 350 | 7.6 | 90 | 120 | |

| 15” | 370 | 7.6 | 98 | 120 | |

| 15 3/4” | 400 | 7.6 | 105 | 120 | |

| 17 3/4” | 450 | 7.6 | 118 | 120 | |

| 19 11/16” | 500 | 7.6 | 150 | 120 | |

| 22 10/16” | 550 | 7.6 | 165 | 120 | |

| 6” | 600 | 7.6 | 170 | 120 | |

| 25 19/32” | 650 | 7.6 | 190 | 120 | |

| 27 1/2” | 720 | 7.8 | 210 | 120 | |

| 29 1/2” | 760 | 7.6 | 220 | 120 | |

| 15 3/4” | 400 | 9 | 105 | 175 | |

| 17 3/4” | 450 | 9 | 125 | 175 | |

| 19 11/16” | 500 | 9 | 145 | 175 | |

| 22 10/16” | 550 | 9 | 165 | 175 | |

| 6” | 600 | 9 | 175 | 175 | |

| 25 19⁄32” | 650 | 9 | 190 | 175 | |

| 27 1/2” | 720 | 9 | 210 | 175 | |

| 29 1/2” | 760 | 8.8 | 220 | 175 | |

| 31 1/2” | 800 | 8.8 | 225 | 175 | |

| 36 7/32” | 920 | 9 | 265 | 175 | |

| 40 5/32” | 1020 | 9 | 295 | 175 | |

| 47 1/4” | 1200 | 9 | 320 | 175 | |

| 51 3/16” | 1300 | 9 | 330 | 175 | |

| 59 1/16” | 1500 | 9 | 460 | 175 | |

| 11 5/8” | 300 | 12 | 80 | 265 | |

| 15 3/4” | 400 | 12 | 105 | 265 | |

| 19 11/16” | 500 | 12 | 150 | 265 | |

| 6” | 600 | 12 | 175 | 265 | |

| 25 19⁄32” | 650 | 12 | 190 | 265 | |

| 29 17/32” | 750 | 12 | 220 | 265 | |

| 31 1/2” | 800 | 12 | 225 | 265 | |

Note: Custom sizes, lengths, and locking head styles are available depending on project needs.

4. Key Selection Mistakes to Avoid

1. Joining Short Ties to Fit Large Bundles

Avoid connecting multiple short zip ties to secure a large bundle—this significantly reduces overall strength and reliability. Always choose a single tie with sufficient effective length.

2. Overlooking material suitability for the environment

Even with the right zip tie sizes, using the inappropriate material can cause premature failure.

Always consider whether the application requires UV resistance, heat resistance, cold tolerance, or outdoor durability.

Conclusion

Zip tie sizing has a direct impact on installation efficiency and long-term reliability.

To ensure the best results, we recommend evaluating size selection based on a combination of factors—including application environment, bundle specifications, and on-site installation conditions.

If you need help selecting the right cable tie sizes for your project, we offer:

- Complete size reference charts

- Free samples for testing

- Technical support and application-specific recommendations

Feel free to contact us for tailored guidance based on your industry or use case.