Many people consider stainless steel cable ties the strongest type of tie on the market. Compared to nylon cable ties, they are known for being more durable and more secure. So why do some users say they “don’t stay tight”? That might sound surprising, but it’s actually a common piece of feedback.

In this article, we’ll look into the reasons behind this issue and see if there are any ways to fix it.

Here we’re referring to the standard self-locking stainless steel cable tie with a ball-lock mechanism, also known as a metal zip tie. Most of these ties are made from 304 or 316 stainless steel, which offer excellent resistance to corrosion, high temperatures, and harsh environments. When people say it “doesn’t stay tight,” it doesn’t mean there’s something wrong with the product. In most cases, the issue comes from its design. While this design works well for holding things together in most situations, it may not grip tightly against certain objects in special cases.

How Stainless Steel Cable Ties Work: The Ball-Lock Mechanism

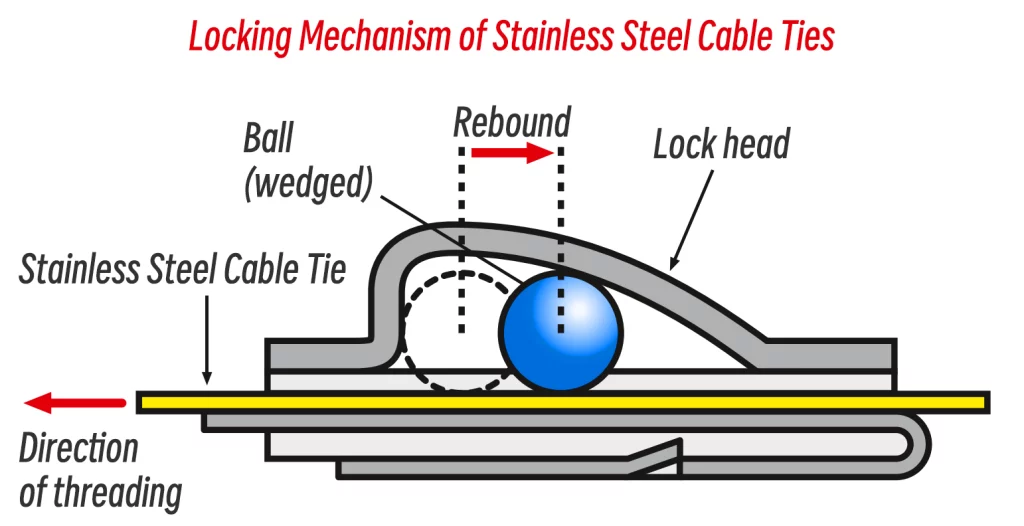

Self-locking stainless steel cable ties use a ball-lock mechanism to secure the tie. The working principle is simple but effective: as the strap is pulled through the head, it pushes a small stainless steel ball inside the locking chamber. The head is designed with a narrow front and wider back, so when the strap is pulled back, the ball wedges itself tightly between the strap and the head, locking the tie in place.

This structure allows for strong locking without the need for tools, making it ideal for heavy-duty applications such as securing large equipment, cable bundles, and industrial components.

If you’d like to learn more about how this locking system works, you can refer to our article: Explore the Locking Mechanism of Stainless Steel Cable Ties.

The “Backlash” Effect

Although the ball-lock design provides a strong holding force, it can cause a slight backlash after locking. This happens because, once you stop pulling the strap, the ball may roll back just a tiny distance—about half a turn—along with the strap. This leads to a small amount of slack.

Why Do Stainless Steel Cable Ties Sometimes Feel Loose?

In most regular applications, this slight movement has little effect on the overall performance. However, when used on hard, smooth, and non-flexible surfaces, even a small gap can prevent the tie from fitting tightly. This can create a sense that the tie is slightly loose or not fully secure.

This is the main reason why some users feel that self-locking stainless steel cable ties don’t always stay tight—not because of a product defect, but due to the design’s mechanics in certain conditions.