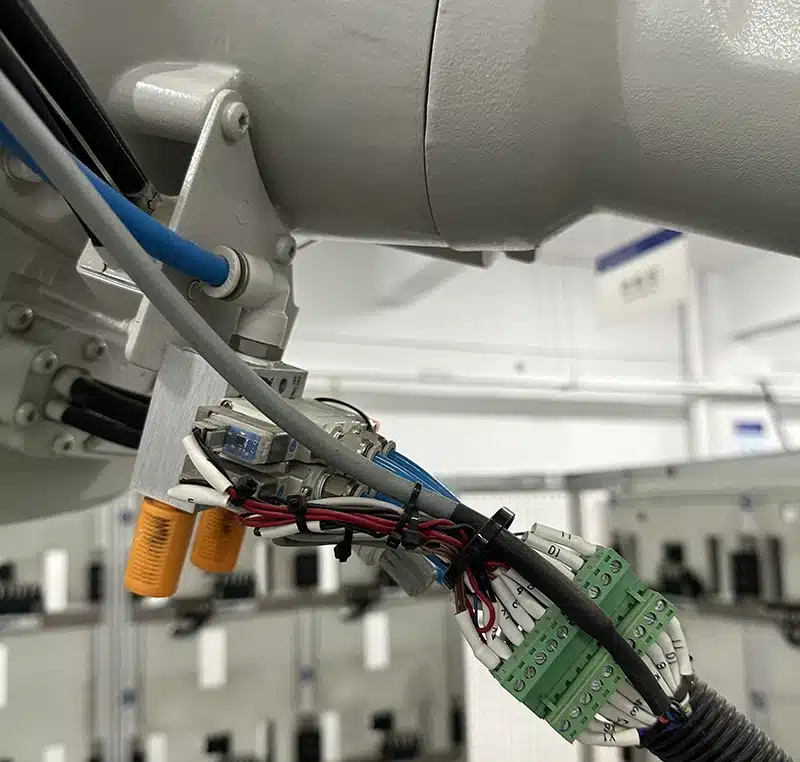

Cable ties play a crucial role in the field of industrial robotics. ABB, FANUC, KUKA, and Yaskawa are among the top four brands globally, with their robotic arms widely used in various manufacturing facilities for high-precision, high-efficiency automated operations. A closer look at these sophisticated machines—often worth tens or even hundreds of thousands of dollars—reveals extensive use of cable ties on their arms. In this piece, we’ll take a set of real-life photos of ABB robotic arms as an example to illustrate how these ties are applied.

What Is a Robotic Arm?

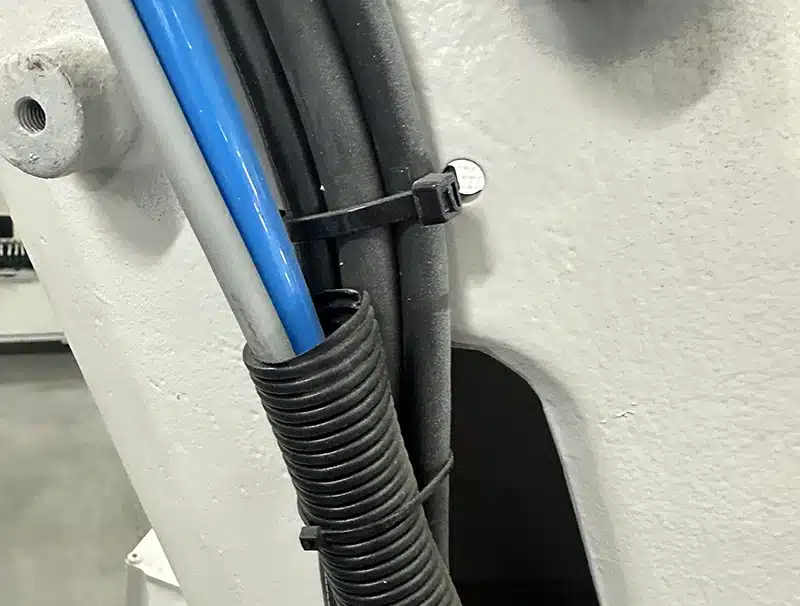

(Photos courtesy of our Director, Tom)

A robotic arm is an automated control device capable of imitating the functions of a human arm and performing a variety of tasks. The first industrial robotic arm in the world, called “Unimate,” was invented in 1956 by Joseph Engelberger, who is often referred to as the “Father of the Robotic Arm.”

Working Principle and Structure of a Robotic Arm

1. Working Principle

A robotic arm operates in much the same way as a human arm, executing precise and refined movements according to a computer-programmed sequence. For example, when it needs to pick up an object, the control system issues a command → the motor drives the joints → sensors provide position feedback → and the task is completed. It’s similar to a person reaching out to grab a cup, but with accuracy levels that can reach 0.02 millimeters!

2. Structure of a Robotic Arm

A robotic arm’s structure can be divided into the following parts:

- “Brain”: The control system (computer program)

- “Muscles”: Motors and drive units

- “Skeleton”: The robotic arm itself and gripper mechanisms

- “Nerves”: Sensors and wiring

In a typical control system, the setup includes a computer, input and output modules, as well as a control program. The computer receives signals from the input module, processes them via the control program, and then sends commands to the motors through the output module. Those motors, in turn, move the links in the robotic arm according to predefined paths or motion logic. Once user input is provided, the control program automatically executes, enabling full automation of the robotic arm.

Why Are Cable Ties Used on Robotic Arms?

After reviewing how robotic arms operate, their structure, and their control systems, it’s easy to see that an industrial robotic arm routes a large number of cables and hoses. These can include servo motor cables, feedback lines, pneumatic or hydraulic hoses, as well as network cables and safety circuits.

Each joint may require multiple power, signal, and control lines, plus wiring for sensors and auxiliary devices, creating an extremely complex wiring setup. In such a demanding environment, maintaining high-speed, stable operations relies on excellent cable management. That’s where cable ties come in, serving as the key tool to keep everything well organized.

Why Are Cable Ties Indispensable in Robotic Arms?

- Quick and Simple to Use

Cable ties feature a self-locking design: just pull to tighten and snip to remove, with no complex tools needed. For robotic arms, this fast wiring method and easy adjustability significantly boost efficiency. - Durable and Reliable

Made largely from PA66 (Nylon 66), these ties offer excellent tensile strength, wear resistance, and weatherability, staying secure in high-speed, high-frequency operations. In daily repetitive motions and vibrations, inferior ties could easily loosen or damage cables. - Smooth and Flexible, Minimizing Wear

Compared to stainless steel ties, nylon cable ties have a smooth surface and inherent flexibility, preventing excessive rubbing or scratching on cables during frequent robotic arm movements. This not only extends cable life but also increases overall system reliability. - Space-Saving

Small and discreet, cable ties can be used efficiently in the tight confines of a robotic arm’s structure without hindering its movement or range of motion. - Cost-Effective

In large-scale production or cost-sensitive projects, small nylon cable ties might cost just a fraction of a cent per piece, yet they deliver highly effective cable management. - Safety and Versatility

Regardless of the brand—whether ABB, FANUC, or KUKA—each robotic arm setup demands stable, universal cable management. Thanks to the broad range of cable tie sizes, cable ties can accommodate diverse wiring requirements, all while minimizing the safety risks that come from loose or tangled cables.

Cable Ties and Robotic Arms

Whether it’s the early Unimate or today’s ABB YuMi, even as technology advances, these robots still rely on efficient, secure cable management to ensure high-speed, precise, and safe operations. cable ties, with their durability, flexibility, low cost, and ease of installation, continue to play an irreplaceable role in these demanding environments. Each firmly secured tie may seem small, but it provides a solid foundation for the robotic arm’s accuracy and reliability.