When looking inside a BMW motorcycle—such as during maintenance or routine inspection—it is easy to notice nylon cable ties used throughout the bike’s interior. They can be found around the under-seat electrical compartment, along wiring routes on the frame, and near various electronic components. Small and easy to overlook, these cable ties nevertheless play a continuous role in organizing and securing the internal wiring harness.

These cable ties are not applied at random. Whether along the inner side of the frame, around control modules, or near areas exposed to vibration, the placement, tightening level, and fixing method of the nylon cable ties are closely related to the motorcycle’s stability and long-term durability during operation. Unlike what many people associate with ordinary plastic cable ties, their role here is not simple bundling, but rather positioning and preventing movement, ensuring that the wiring remains where it is intended to be.

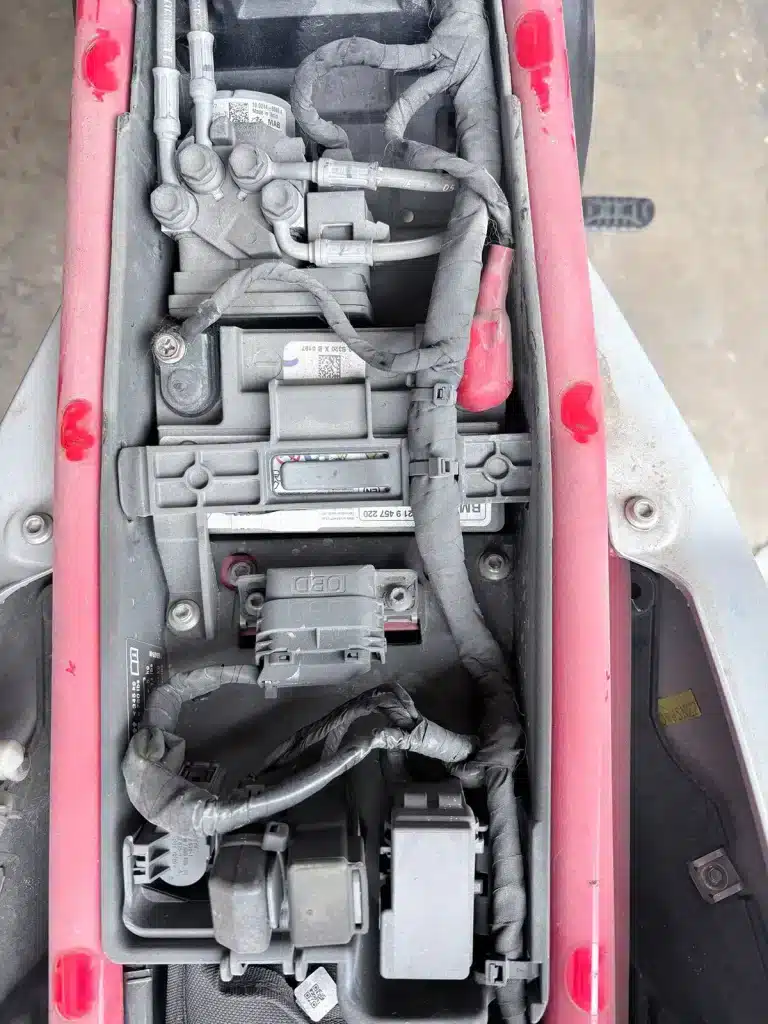

In this article, we take a closer look at the actual applications of cable ties inside BMW motorcycles through on-site photographs. By examining these details, it becomes easier to understand how such seemingly minor components contribute to the overall wiring layout and long-term reliability of the motorcycle.

Where Cable Ties Are Used Inside BMW Motorcycles

1. Fixation and Organization in the Original Design

In the wiring design of BMW motorcycles, cable ties are commonly used for final fixation at specific points. As seen in the photographs, inside the under-seat electrical compartment, wiring harnesses are typically first wrapped with fabric tape as a whole, and then secured in sections using nylon cable ties. The purpose of this approach is not to tighten the harness as much as possible, but to prevent it from shifting under long-term vibration or rubbing against surrounding components.

Another typical application can be found around the battery area. Here, cable ties keep the surrounding cables routed along predefined paths, preventing them from becoming loose or disorganized, while also making the battery compartment neater and easier to service.

2. Practical Support During Maintenance and Modifications

Around the red frame tubes and the battery area, the photographs show nylon cable ties holding the wiring harness in relatively safe positions. The harness is routed as close as possible to the inner side of the frame, kept away from sharp edges and areas that may be compressed by the seat, while connectors and interfaces are arranged in a more orderly manner.

The immediate benefit of this approach is that the wiring is less likely to “wander” under vibration, reducing the risk of long-term contact and abrasion against metal structures. From a maintenance perspective, after removing and reinstalling the battery or checking connectors, following the original cable tie positions to return the wiring harness to its intended route makes it less likely to pinch, misroute, or trap cables during reassembly.

In addition, once the wiring is grouped and fixed in this way, the electrical compartment appears much more organized. Service access paths are kept clear, and cables that should remain along the edges do not spill into the central area, which helps both assembly and later identification during servicing.

3. Usage Details and Practical Considerations

The photographs show that original assembly and professional maintenance work pay close attention to how cable ties are used. Several details are particularly noticeable:

Consistent orientation:

The locking heads of the cable ties are usually oriented toward the inner side of the frame or downward. This not only looks cleaner, but also helps reduce the risk of snagging on nearby components or wiring.

Trimmed excess length:

After tightening, the excess tail of the cable tie is cleanly cut off using proper cutting tools, leaving a smooth, short edge. This helps prevent sharp ends from scratching wire insulation or injuring hands during maintenance.

Protective buffering:

In areas where cable ties are in direct contact with wiring or hoses and friction may occur, an additional layer—such as insulating tape or a flexible protective sleeve—is often applied first. The cable tie is then used to secure the protected section, providing vibration damping and abrasion resistance.

Avoiding over-tightening:

When fixing wiring harnesses, cable ties are typically tightened only until the harness no longer moves. Excessive tightening can compress the wires and, over time, damage the insulation, reducing long-term reliability.

Conclusion

These close-up details show that cable ties inside BMW motorcycles are far from being optional or insignificant components. While they do not serve as load-bearing elements, they play an important role in the wiring system by providing positioning, preventing movement, and supporting orderly routing. Through these functions, wiring harnesses are able to remain stable under long-term vibration and varying temperature conditions.

Correct and consistent use of cable ties helps keep the motorcycle’s interior organized, reduces the risk of wiring damage, and contributes to overall electrical safety and component longevity. Although small and easily overlooked, cable ties represent a simple but essential part of a well-designed and reliable internal layout.