When cable tie colors are mentioned, most people think first of black and natural white. These two options are indeed the most common and cover a large share of everyday applications. However, in real-world use, cable ties are available in far more than just these two colors. Red, blue, green, yellow, and other colored cable ties are widely used in specific situations, and in some cases, colors are even selected or customised based on project needs.

In practice, color is not just a visual choice. It often serves a functional purpose related to identification, organisation, and management. Whether cable ties are used to separate circuits, mark batches, or support different installation stages can directly influence color selection. In other words, choosing the right color is usually about how and where the cable ties are used—not simply about appearance.

The Two Most Common Colors: Natural and Black

Among all nylon tie colors, natural (often referred to as white) and black are by far the most widely used. This is not simply because they are cheaper than colored options, but because long-term industrial use has gradually made them the default choice for various scenarios.

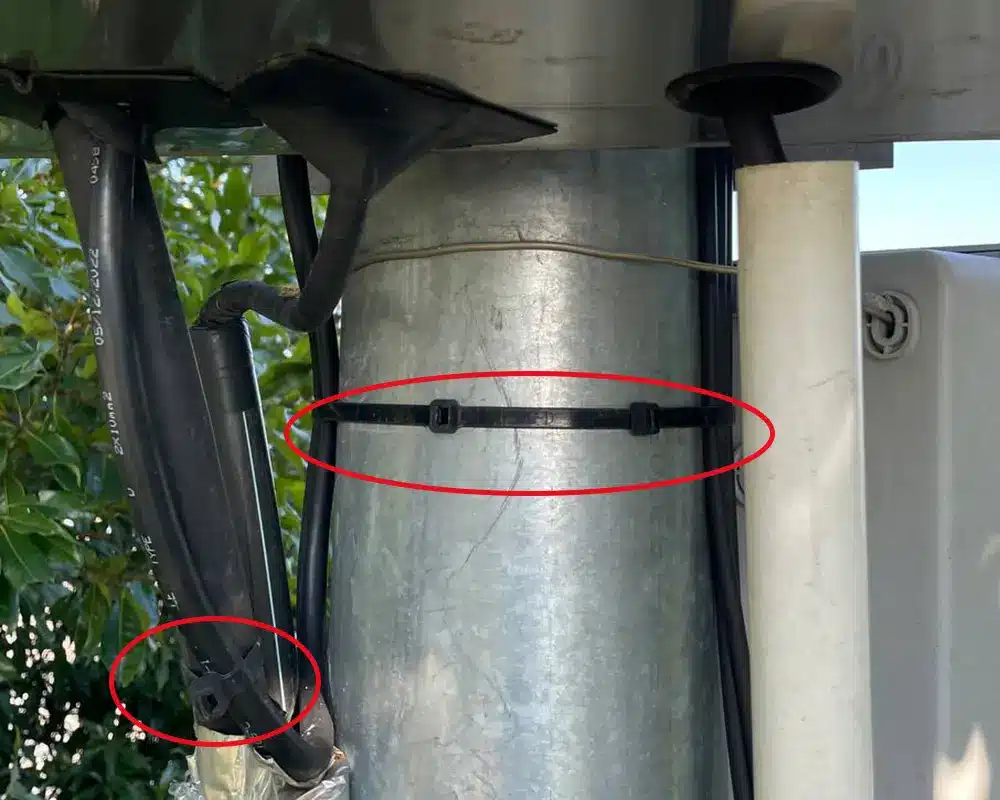

In many electrical and engineering environments—such as control cabinets, equipment interiors, and outdoor power or communication lines—the cables themselves are already black. Using black cable ties in these situations helps the fixing blend into the overall layout, avoids visual clutter, and does not interfere with other identification systems. This subtlety is often important on real job sites, where clarity and consistency matter more than visibility.

Natural cable ties, by contrast, function more as a general-purpose fixing option. They are commonly used during early installation stages, temporary setups, or in locations where appearance is not critical. Their lighter color also makes it easier to visually inspect the tie itself, which can be useful when checking installation status or making quick adjustments.

Colored Cable Ties and Their Practical Uses

In terms of material and basic performance, colored cable ties are not fundamentally different from natural or black ones. They are typically produced using the same base material, PA66, with color introduced through masterbatch additives during the manufacturing process. As a result, color alone does not mean reduced strength or lower performance—it simply extends the range of use cases.

- The real value of colored cable ties lies in identification, organisation, and management. In electrical and equipment-related applications, different colors are often used to distinguish circuits, functions, installation stages, or batches. During temporary work, commissioning, or maintenance, color-based identification allows technicians to recognise cable groups quickly without relying on additional labels, which can fall off or become unreadable over time.

- In gardening and agricultural settings, color serves a more contextual purpose. Green and brown cable ties are commonly used to secure plants, branches, or support frames because they visually blend into the surrounding environment. Compared with black or natural ties, these colors are less noticeable in greenhouses, nurseries, and orchards, making them a more practical choice where appearance and integration matter.

- Colored cable ties are also widely used for batch and time management. In agricultural and logistics-related scenarios, different colors can represent harvesting periods, production batches, or processing stages. Color becomes a form of non-verbal marking—simple, durable, and easy to recognise at a glance.

- Beyond industrial use, colored cable ties are frequently seen in DIY projects, craft work, and temporary decorative setups. While these are not their primary applications, they highlight the flexibility that color brings, allowing cable ties to move beyond pure fixing and into basic visual organisation.

Overall, the difference between colored and non-colored cable ties is not cosmetic. Color directly shapes how cable ties are used, managed, and understood on site.

Conclusion: Color Is Part of How Cable Ties Are Used

Looking across natural, black, and colored cable ties, a clear pattern emerges: color follows function. Natural ties serve as a general-purpose fixing option, suitable for situations where differentiation is not required. Black cable ties are often chosen to match cables and equipment layouts, especially in electrical and engineering environments where visual consistency matters. Colored cable ties, on the other hand, play a direct role in identification, organisation, and management.

There is no single “best” color. The right choice depends on where the cable ties are used, how they are used, and what needs to be identified or managed. In practical applications, color is not decoration—it is part of the working logic. Understanding this makes it easier to select nylon ties that fit the task, rather than choosing based on appearance alone.

Appendix: Practical Reference for Choosing Cable Tie Colors

| Application Scenario | Common Colors | Reason for Selection |

| Electrical cabinets, electrical equipment, cable management | Black | Matches cable color, visually unobtrusive, does not interfere with existing identification systems |

| Indoor equipment, general-purpose fixing | Natural (white) | Versatile, easy to use, allows quick visual inspection of installation conditions |

| Outdoor or strong light exposure | Black | Generally offers better weather resistance |

| Gardening, greenhouses, nurseries | Green / Brown | Blends into the environment and avoids visual distraction |

| Batch, time, or process identification | Multiple colors | Color-based marking improves recognition efficiency without relying on text labels |

| DIY, craft, decorative use | Colored | Flexible and visually expressive for creative applications |

| Medical or food-related applications | Natural (white) | Clear color allows easier inspection of cleanliness and potential contamination |