In a distribution cabinet, where wiring is dense and complex, cable ties serve as an essential and cost-effective solution for cable management.

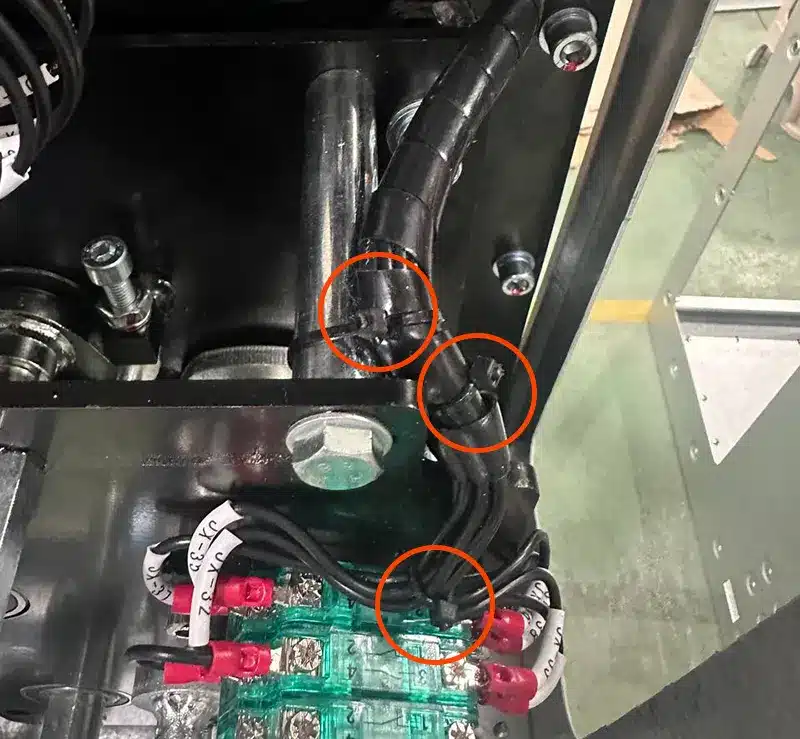

These cabinets often contain a large number of power, signal, and control cables. Messy wiring can easily lead to equipment failure or even safety hazards without proper organization.

In this article, we’ll take a real-world look at how cable ties help solve the challenges of managing cluttered wiring inside distribution cabinets, making systems cleaner, safer, and easier to maintain.

1. What Is a Distribution Cabinet?

A distribution cabinet is like the “traffic control center” of an electrical system—or the “main manager” of a building’s power network. It receives incoming power and redistributes it to various devices, ensuring that the entire system runs safely and efficiently.

In technical terms, a distribution cabinet is a core piece of equipment for power distribution, circuit control, and electrical protection.

Take a mid-sized industrial distribution cabinet as an example. It may contain dozens or even hundreds of cables, each with a specific function, such as main power cables, control signal wires, and grounding lines. Without proper organization, these cables can easily become tangled or cross over each other, leading to poor ventilation, difficult maintenance, and increased risk of failure.

That’s why tools like cable ties, wire ducts, and labeling systems are essential for managing the cables inside. Neatly routing and securing them in layers not only keeps the system clean but also helps ensure long-term reliability.

2. How Cable Ties Help Manage Wiring Inside Distribution Cabinets

1. Improve Cable Clarity and Layout

By using cable ties to bundle power and signal lines separately and in layers, you can create a modular, well-organized layout. Clear and structured wiring makes it easier for maintenance staff to identify, trace, and troubleshoot circuits quickly and accurately.

2. Enhance Operational Safety

Nylon cable ties offer strong insulation and secure fastening, which helps reduce cable wear and vibration during equipment operation. This lowers the risk of electrical faults and contributes to a safer and more stable system.

3. Reduce Maintenance Costs

When used together with labeling cable ties, each cable can be marked with its function or number. This greatly reduces labor time during maintenance and lowers the overall cost of equipment servicing.

3. How to Choose the Right Cable Ties for Distribution Cabinets

In environments like distribution cabinets, where cable management is critical, selecting the right type of cable tie directly affects both performance and long-term reliability. Here are the key selection points to consider:

Cable Tie Sizes

The diameter and number of cables being bundled will determine the appropriate tie size. Common specifications include 2.5×150mm and 3.6×200mm.

- For thinner control wires, 2.5×150mm ties are usually sufficient.

- For thicker power cables or multiple wires bundled together, opt for 3.6×200mm or wider ties to ensure a secure hold.

Material

We recommend UL-certified PA66 (Nylon 66) cable ties. They offer excellent tensile strength, electrical insulation, and heat resistance—ideal for demanding electrical environments.

Color

Since space inside a distribution cabinet is limited, good visual identification improves maintenance efficiency.

- Black cable ties are commonly used for general bundling.

- White or natural-colored ties are suitable for identifying specific cable groups or marking important circuits.

Cable Ties: A Small Tool with Long-Term Value in Wire Management

Nylon cable ties may seem minor, but they play a vital role in managing cables inside distribution cabinets. From improving layout clarity and ensuring safe operation to reducing maintenance time, they help bring order and reliability to complex wiring systems.

As smart power distribution systems evolve, the need for organized cable management will continue to grow. Standardized use of cable ties is a low-cost yet high-impact practice—a small detail that supports long-term system efficiency and safety.