The guide to metal cable ties offers a comprehensive introduction to metal cable ties, assisting users to understand better and utilize this powerful and practical tool. Renowned for their exceptional corrosion resistance, high-temperature tolerance, and remarkable tensile strength, stainless steel cable ties have become indispensable in many industries. Whether used for securing heavy cables or binding equipment in extreme conditions, they provide a reliable and efficient solution.

This guide thoroughly presents the various features, design principles, and application areas of stainless steel cable ties. It also provides detailed instructions on installation, usage, and maintenance to ensure that users can select and apply this versatile tool more proficiently.

Material of Metal Cable Ties

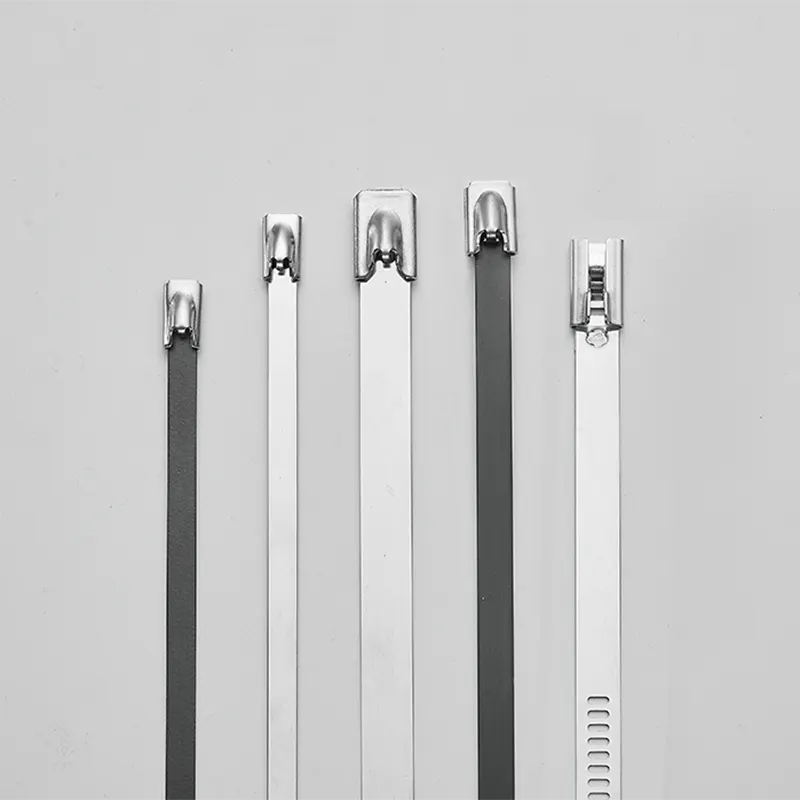

Metal cable ties are typically made from types of stainless steel, such as 304 or 316, which are extensively utilized due to their excellent corrosion resistance and high-temperature endurance. For instance, 304 stainless steel is suitable for most environments because of its good corrosion resistance and cost-effectiveness. In contrast, 316 stainless steel offers higher corrosion resistance, making it ideal for more demanding conditions like marine environments. For a detailed comparison of the performance characteristics of these materials, refer to the article “Metal Zip Ties Material and Applications“.

3 Key Performance Characteristics of Metal Cable Ties

1. Corrosion Resistance:

Metal cable ties, made from 304 or 316 stainless steel, effectively resist chemical corrosion and oxidation. They are ideal for long-term exposure to marine salt spray and corrosive chemicals, exhibiting excellent durability.

2. High-Temperature Resistance:

Metal cable ties can perform reliably in environments with temperatures up to 538°C (1000°F) without deforming or sustaining damage from the heat. This makes them particularly suitable for high-temperature applications such as automotive engine components, and thermal installations.

3. Strength and Durability:

Even standard-sized stainless steel cable ties, with widths of 4.6mm and 7.9mm, can achieve tensile strengths ranging from 100 kg to nearly 300 kg. Such high tensile strength ensures that they retain their securing strength even under heavy loads or in long-term applications.

How Do Metal Cable Ties Work

The design of stainless steel cable ties takes into account a variety of usage environments and requirements, with the self-locking mechanism being a core feature. The ball-lock design principle allows the ties to be securely fastened by hand, without the need for any tools. As the tie passes through the head of the cable tie, the ball tightly engages with the tie, tightening it and preventing backsliding, thus achieving an automatic locking effect. The locking mechanism of stainless steel cable ties is detailed further in the article “Explore the Locking Mechanism of Stainless Steel Cable Ties.”

Application of Metal Cable Ties

Exploring the application of metal cable ties reveals their extensive use across multiple industries. Their robust functionality and adaptability make them an ideal choice for a variety of engineering and manufacturing processes.

In the construction industry, stainless steel cable ties are commonly used to securely fasten cables, pipes, and other critical components. Their strength and corrosion resistance make them particularly suitable for outdoor environments and exposure to harsh weather conditions.

Metal cable ties also play a vital role in the maritime and aviation industries. On ships, they are used to secure equipment and pipelines against strong sea winds and salt spray. In aviation, these ties ensure the safe securing of internal cables and components of aircraft, even under extreme flying conditions.

The automotive manufacturing industry also widely adopts metal cable ties. Here, they are utilized to organize and secure wiring harnesses, ensuring the safety and reliability of the vehicle’s electrical system.

Furthermore, in electrical engineering, the heat resistance and durability of metal cable ties make them an ideal tool for cable management. They are used to organize cables, preventing looseness and damage, thereby ensuring the stability and safety of the electrical system.

In summary, the versatility and reliability of metal cable ties in various industries render them indispensable components in diverse applications.

How to Use Metal Cable Ties

Before using metal cable ties, it’s crucial to select the size. Begin by choosing ties of appropriate width and length based on the size and weight of the object to be secured. Generally, heavier or larger objects require wider ties to ensure the chosen tie can withstand the tensile strength needed in practical applications. Next, choose tools for trimming any excess part, like scissors or cable tie tools, to avoid safety hazards from extra material.

Steps for using metal cable ties:

- First, thread the tie through the object you need to secure and then through the locking mechanism at the head of the tie. Ensure the tie fits snugly around the object but not too tightly to prevent damage.

- Use a tightening tool to adjust the tightness of the tie as needed, tightening it. Then, use the tool to cut off the excess tail of the tie.

- Finally, check the lock of the tie to ensure it is secure and ensure the cut end is smooth to avoid sharp edges.

For detailed instructions and diagrams, refer to the article “How to Use Stainless Steel Cable Ties Exploring 2 Effective Methods.”

Maintenance and Storage of Metal Cable Ties

Unused metal cable ties should be kept in a dry, ventilated environment for storage. Avoid placing them in direct sunlight, high-temperature areas, or near chemicals, as these conditions can impact their performance.

Regarding other issues, such as ties being too loose or too tight, the solution often involves adjusting the tightness of the tie or reinstalling it. If a tie is overly tight, it may need to be loosened or cut and reinstalled. For guidance on how to untie metal cable ties, the article “How to Loosen a Stainless Steel Cable Tie in 3 Steps” offers illustrated instructions.

A Comprehensive Guide to Metal Cable Ties

In summary, with their simple yet efficient, sturdy, and durable characteristics, metal cable ties meet the demands of both industrial and everyday applications. We hope this guide provides you with useful information, helping you better understand and utilize metal cable ties. Whether for daily small repair tasks or professional-grade engineering projects, appropriately chosen metal cable ties will be one of your most reliable tools.