In the UK, stainless steel cable ties are widely used for long-term outdoor fixing, and stainless steel banding with an Ear-Lokt buckle is often chosen because they stay secure under wind, vibration, and long maintenance cycles.

In practice, these stainless steel ties are frequently used to secure road signs, equipment boxes, and other street-side fixtures. Depending on the size of the object and the load involved, the Ear-Lokt banding may be installed as a single strap or in multiple parallel runs, and is typically left in place for years as a permanent fixing.

Compared with nylon cable ties, stainless steel cable ties with an Ear-Lokt buckle are selected not for installation speed, but for long-term stability. Their all-metal structure and clear load path make them well-suited to continuous outdoor exposure.

What Is Ear-Lokt Stainless Steel Banding?

(A Type of Stainless Steel Cable Tie)

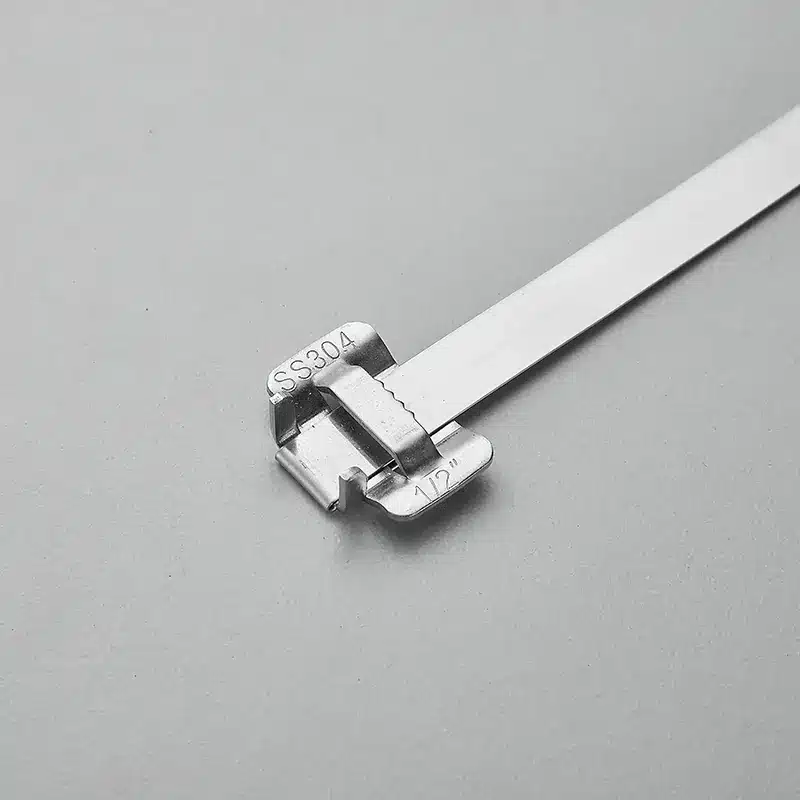

Ear-Lokt stainless steel banding is a common form of stainless steel cable tie used in the UK outdoor environments. Made from 304 or 316 stainless steel, it uses an all-metal Ear-Lokt buckle to clamp the steel band mechanically, preventing any back-slip once the band is tensioned and crimped.

Unlike nylon cable ties or ball-lock stainless steel designs that rely on molded locking components, the Ear-Lokt system depends entirely on metal clamping force. It is not intended for quick or tool-free installation, but for permanent, long-term fixing. Once properly set, the band and buckle maintain a stable clamping force over time, which is why this type of stainless steel cable tie is widely used on road signs, poles, and outdoor fixtures across the UK.

Structure: Separate Band and Ear-Lokt Buckle

Ear-Lokt stainless steel banding consists of two separate components: a stainless steel band and an independent Ear-Lokt buckle. The band and buckle are typically supplied as individual parts. They are assembled during installation by positioning and crimping the buckle onto the band to form a complete stainless steel cable tie.

This separated design provides two practical advantages. First, the band length can be selected freely, allowing the system to accommodate objects with different diameters. Second, both the steel band and the Ear-Lokt buckle are relatively thick, enabling the assembly to achieve a high and consistent locking force. From an engineering perspective, this structure is closer to a standardized mechanical fastener than to a disposable plastic cable tie, which explains its widespread use in industrial and infrastructure applications.

How It Works: Mechanical Clamping with an Ear-Lokt Buckle

Locking is achieved through a purely mechanical clamping process. After the steel band passes through the Ear-Lokt buckle, it is pulled tight, folded back, and pressed flat. The buckle tabs are then crimped, clamping the band securely and preventing any backward movement.

The reliability of the Ear-Lokt system comes from two factors. The folded band creates a double-layer load path, while the crimped buckle provides continuous metal clamping force and a positive mechanical stop against slip. Under long-term vibration, wind load, and temperature changes, this all-metal locking method remains stable.

Installation Process: Thread–Tension–Fold Back–Crimp–Set

In the field, stainless steel cable ties using Ear-Lokt stainless steel banding are typically installed through the following steps:

- Threading: The stainless steel band is fed through the Ear-Lokt buckle and wrapped around the object to be secured.

- Tensioning: The band is pulled tight by hand or with a tensioning tool to achieve the required clamping force.

- Folding back: Excess band is folded back along the direction of the main band and pressed flat.

- Trimming: Any remaining excess length is cut off.

- Crimping: The tabs of the Ear-Lokt buckle are pressed down to clamp the band firmly in place.

- Setting: The tabs are hammered or pressed fully to ensure the buckle is properly set and cannot spring back or loosen.

Compared with nylon cable ties, this installation requires more effort and typically involves tensioning and crimping tools. However, once properly set, the all-metal Ear-Lokt fixing provides long-term stability and does not loosen under vibration or outdoor exposure.

Why Stainless Steel Cable Ties with Ear-Lokt Buckles Suit UK Outdoor Environments

The UK does not often experience extreme outdoor conditions, but stainless steel cable ties used on street signs, poles, and equipment boxes are exposed to wind and rain for long periods of time. Maintenance intervals are typically long, and access is often limited. In these situations, fixing methods are selected not for installation speed, but for their ability to remain stable over time.

In many UK outdoor installations, the solution used is stainless steel cable ties based on Ear-Lokt stainless steel banding. Once the steel band is folded back and clamped by the Ear-Lokt buckle, the system forms an all-metal fixing with a clear and stable load path. After crimping, the locking state remains fixed, making this type of stainless steel cable tie resistant to loosening under long-term wind load and vibration.

For this reason, although stainless steel cable ties using Ear-Lokt buckles require tools and more effort during installation than nylon alternatives, this is not considered a disadvantage in UK outdoor use. A one-time, properly executed installation reduces the risk of later movement or rework, which aligns well with the maintenance logic of outdoor infrastructure.

Typical UK Applications of Stainless Steel Cable Ties

In UK urban environments, stainless steel cable ties are most commonly found on the backs of road signs, on lamp posts and poles, and around outdoor equipment boxes. These locations are often irregular in shape and space-limited, and fixing must be completed without drilling or modifying the original structure.

On road signs and directional signage, stainless steel banding with an Ear-Lokt buckle is widely used to secure the sign to a pole. Compared with bolted connections, this method requires no drilling and offers better long-term weather resistance than nylon cable ties, making it suitable for permanent outdoor exposure.

On lamp posts, guardrails, and building columns, stainless steel cable ties using Ear-Lokt banding are frequently used to fix small equipment boxes, cables, or auxiliary components. These applications do not usually demand extreme load capacity. Instead, the key requirement is that the fixing remains stable under wind and vibration without shifting or loosening—conditions where Ear-Lokt stainless steel cable ties perform well.

From on-site observation, stainless steel cable ties may be installed as a single band or in multiple parallel runs, depending on the size of the object and the load involved. This flexibility contributes to their wide adoption in UK outdoor environments.

Conclusion

Based on real-world use across UK streets and public infrastructure, stainless steel cable ties with ear-lokt buckle can be regarded as a long-term fixing solution that has been repeatedly validated in practice. Rather than prioritising ease of installation, this design relies on an all-metal clamping structure to deliver stable and predictable performance in outdoor conditions.

This does not mean that ear-lokt banding is suitable for every application. In UK outdoor installations, other forms of stainless steel cable ties—such as ball-lock designs—as well as hose clamps are also widely used. The final choice depends on installation location, load requirements, and maintenance strategy.

Future articles will explore how different types of stainless steel cable ties are used in the UK and how to select the most appropriate option for specific outdoor applications.