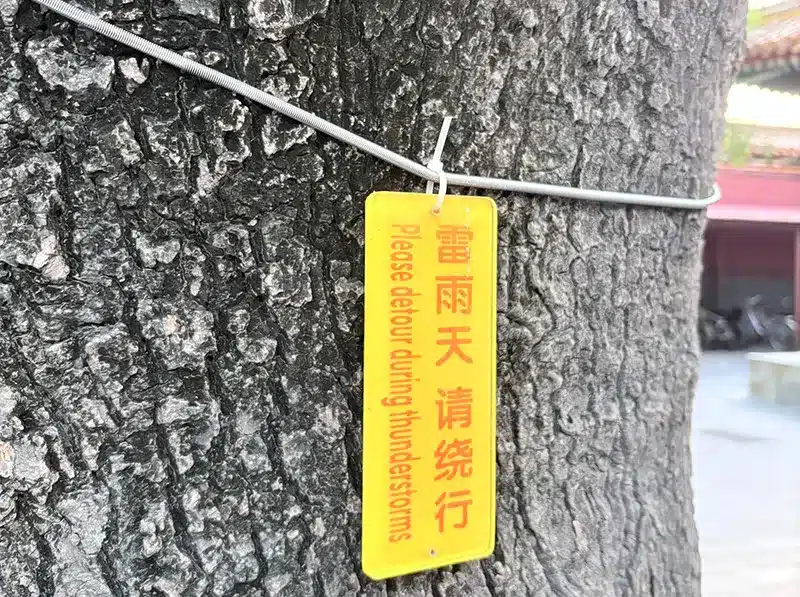

If you walk through Yonghe Temple (Lama Temple) in Beijing, China — a 300-year-old imperial monastery — you’ll notice something interesting among the ancient wooden beams and traditional courtyards: a few outdoor cable ties quietly doing their job.

They’re small and unassuming, but surviving years in the outdoor environment of Beijing, China is no easy task. With hot, dry summers, freezing winters, and strong UV radiation, any ordinary plastic would quickly turn chalky and brittle.

The reason those cable ties last so long comes down to materials and weather resistance. And these details raise a few practical questions many people have when choosing outdoor cable ties:

- Why shouldn’t indoor cable ties be used outdoors?

- What type of cable tie is best for outdoor environments?

- Why do different climates require different weather-resistant grades?

Why Indoor Cable Ties Are Not Recommended for Outdoor Use

Even though most cable ties sold globally are made from PA66, standard PA66 is not designed for long-term sunlight exposure. Without UV stabilizers, the polymer chains gradually break down under ultraviolet radiation, causing:

- Surface chalking or fading

- Loss of tensile strength

- Reduced flexibility

- Becoming brittle in winter and soft in high heat

- Eventually snapping with very little force

This is why indoor cable ties usually cannot survive outdoors for more than one or two years, especially in regions with strong sunlight or large temperature swings.

A common misconception—both in Asia and overseas—is that “black cable ties = outdoor cable ties.”

But the truth is: Color alone does not make a cable tie UV-resistant. A black tie without UV stabilizers will still degrade quickly outdoors. At Yonghe Temple in Beijing, China, the outdoor cable ties that stay intact after years of wind, sunlight, and temperature changes are not just “black” or “PA66.”

They are UV-stabilized, weather-resistant PA66 specifically formulated for outdoor applications.

So the real difference between indoor and outdoor cable ties is not material or color, but whether the tie is engineered to resist UV and temperature changes.

Types of UV-Resistant Cable Ties and How They Fit Different Climates

All outdoor cable ties share one essential requirement:

They must be UV-resistant so they can withstand long-term sunlight exposure without chalking or becoming brittle.

Within UV-resistant cable ties, the next level of classification depends on their temperature performance.

Different climates place different demands on how the material behaves in heat, cold, or extreme temperature swings.

Based on temperature range, UV-resistant cable ties can be divided into three main types:

1. Standard UV-Resistant PA66 Cable Ties

Temperature range: For typical outdoor temperatures

Best for: Most countries with moderate climates

Features:

- Added UV stabilizers

- Prevents chalking and cracking

- Suitable for long-term outdoor exposure

2. Cold-Resistant UV Cable Ties (–40°C Rated)

Best for: Regions with severe winters (Russia, Canada, Northern Europe, Northeast China)

Features:

- Modified crystallinity for low-temperature toughness

- Maintains flexibility and strength in freezing conditions

3. High-Temperature UV Cable Ties (up to 120°C)

Best for: Hot climates & heat-exposed installations (South Asia, Middle East, metal surfaces under sunlight)

Features:

- Resistant to continuous heat

- Won’t soften or lose locking strength on hot metal structures

HUADA Plastic: Recommending the Right Outdoor Cable Tie for Different Climates

In real outdoor projects, the performance of a cable tie depends not only on the material itself, but also on whether it matches the local climate, temperature range, humidity, and expected service life. Many users have experienced the same issue: a product looks perfectly fine when purchased, but once installed outdoors in a different climate, it begins to age or crack much earlier than expected.

That’s why, when we work with customers around the world, our first questions are always:

“Where will the product be used?”

“What is the temperature range on site?”

These details matter far more than the model number alone. They determine whether a cable tie can remain stable for years, not just months.

HUADA Plastic has long supplied markets across Russia, the Middle East, Southeast Asia, and Europe. Through these projects, we’ve gained practical experience with each region’s requirements — from UV resistance and color stability to tensile strength and packaging preferences. Whether the environment involves extreme cold, continuous high heat, or year-round sunlight exposure, we can recommend a formulation that fits the climate, not just the specification sheet.

At HUADA, we focus on how our products perform in real-world conditions.

Our goal is simple: to ensure every cable tie delivers long-term stability, wherever it is used.