Are cable ties waterproof? Can they be used outdoors or in damp environments? It’s a question we hear quite often. Many people see that cable ties are made of plastic and naturally assume they’re “waterproof.” But the truth isn’t quite that simple.

At Huada, we’ve been making nylon cable ties for years, and we’d like to share a few things about how nylon reacts to water — and what that really means for your applications.

1. Are Cable Ties Waterproof? — Water-Resistant, But Not Fully Waterproof

First, it’s important to make one thing clear: nylon cable ties have good water resistance, but they are not completely waterproof.

“Fully waterproof” materials — like rubber seals or waterproof connectors — can stay submerged in water for long periods without losing their properties.

“Water-resistant,” on the other hand, means the material can handle humidity, rain, or brief contact with water while maintaining normal performance.

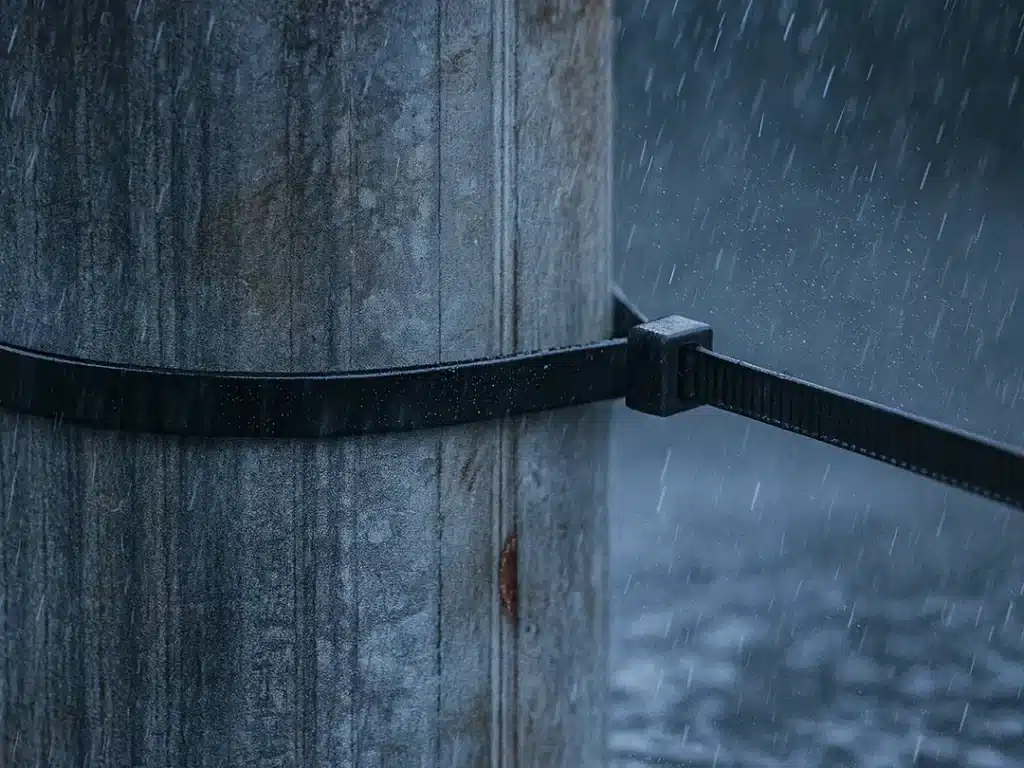

In practice, nylon cable ties are water-resistant, not fully waterproof. They can withstand general moisture and rain, but they are not designed for long-term submersion. In other words, their resistance to water is conditional — it depends on how and where they are used.

- Short-term exposure (performs well):

In conditions such as rain, cleaning, or ambient humidity, the structure of the cable tie remains stable, and its strength is barely affected. - Long-term exposure (performance decreases):

When nylon is soaked in water or exposed to high humidity for a long time, it gradually absorbs moisture. This breaks hydrogen bonds between molecular chains, reducing tensile strength while increasing flexibility.

Typically, the tie’s strength may drop by about 10–20%, and its size may expand slightly after moisture absorption.

So, for most everyday or outdoor uses, cable ties work perfectly fine. But in consistently wet or load-bearing environments, it’s better to choose UV-stabilized or stainless-steel cable ties for longer-lasting performance.

2. From the Material Itself — Why Nylon Cable Ties Absorb Moisture

2.1. Nylon’s “Hydrophilic“ Nature: Absorption Starts at the Molecular Level

Why can’t cable ties be fully waterproof like metal or stainless-steel ones? The answer lies in the nature of nylon itself — it’s a hydrophilic (water-attracting) material.

You can think of nylon molecules as long chains with tiny “magnets” attached — these are called amide groups (–CONH–). Water molecules (H₂O) also behave like small magnets. When nylon comes into contact with moisture in the air or with water directly, the water molecules are attracted to these amide groups and bond through hydrogen bonding.

This is a dynamic process. Nylon continuously absorbs and releases moisture depending on the surrounding humidity — like a material that “breathes.” In normal environments, there is always a small amount of water inside the material. This balance is called equilibrium moisture content. For PA66, it’s around 2.5% at 23 °C and 50% relative humidity.

In other words, nylon doesn’t repel water — it lives with it. That’s why it can’t be “fully waterproof.”

2.2. How Nylon Changes After Absorbing Water

When water enters the molecular structure of nylon, it changes the material’s properties in several ways.

The upside — more flexible and impact-resistant

The absorbed water acts like a natural plasticizer, lubricating the molecular chains and allowing them to move more easily.

That’s why nylon cable ties tend to feel softer and less brittle in humid environments.

The downside — lower tensile strength and stiffness

Because the molecular structure becomes looser, the material loses some of its rigidity.

For example, a cable tie that can hold 22 kg in normal conditions may retain only 80–90% of that strength after full moisture absorption.

Under continuous stress, it can even show creep — a slow stretching effect where the tie gradually elongates and loosens over time.

2.3. Dimensional Effects — Slight Expansion

As water molecules enter, they push apart the polymer chains slightly, causing minor expansion.

However, this size change is usually in the micron range — almost unnoticeable in everyday applications.

Only in precision electrical or mechanical assemblies might this need to be considered.

3. Choosing the Right Cable Ties for Different Environments

Now that we understand how nylon cable ties react to moisture, the key is to choose the right type for your working environment. Nylon performs best when humidity is balanced — it can become softer in overly humid conditions or more brittle when too dry. That’s why it’s important to select cable ties that match your surroundings.

We’ve divided the typical applications into three zones — Green, Yellow, and Red — based on humidity levels and usage conditions:

| Zone | Environmental Conditions | Typical Applications | Recommended Type |

| Green (Safe) | Moderate humidity, normal indoor or outdoor conditions | Indoor wiring, temporary cable bundling, and packaging | Standard nylon cable ties |

| Yellow (Caution) | Constant humidity, exposure to rain or temperature changes | Outdoor signage, gardening, humid workshops | UV-resistant cable ties |

| Red (Not Recommended) | Long-term submersion or extreme humidity/dryness | Constant humidity, exposure to rain, or temperature changes | Stainless steel cable ties |

These categories are mainly based on humidity levels. If your environment also involves high temperatures, strong sunlight, chemical exposure, or heavy mechanical stress, make sure to consider these factors together before choosing your cable ties.

For a more detailed guide, see our article “Cable Tie Selection Guide.”

4. Conclusion: Water-Resistant ≠ Fully Waterproof

Many people assume that “plastic means waterproof,” but that’s not quite true for nylon cable ties. They can handle short-term exposure to rain and humidity, but they will gradually lose strength when submerged in water or placed in extreme hot and humid conditions.

Understanding the material and choosing the right product for the right environment is the key to ensuring both safety and durability, even for something as small as a cable tie.