During a weekend visit to the Tsingtao Beer Museum, I saw a nearly fully automated beer production line. Only one worker was on patrol, while conveyor belts and robotic arms handled all other steps. In such a highly automated environment, cable ties are used everywhere: around motors, robotic arms, sensors, and pipes. They secure cables, air hoses, and sensor wires firmly in place, keeping the site neat and orderly.

In fact, the use of cable ties on beer production lines can be traced back to the 1980s, when China’s first canned beer production line was launched in Tsingtao. The equipment at that time was far from fully automated, but even in black-and-white photos, you can clearly see workers already using nylon ties to fix cables. Today, the production line is fully automated, yet ties are still found in every corner. Whether it was the production line of more than 40 years ago or today’s smart factory, cable ties remain one of the essential accessories.

Below is a set of on-site photos showing different applications of cable ties on the canned beer production line.

Application Scenarios of Cable Ties

1. Motors and cable management

On composite packaging machines, motors are the core power components, often surrounded by cables of different sizes. Cable ties group and secure these cables, preventing them from rubbing against each other or being damaged by moving parts. For motors running at high speed over long periods, stable cable management helps reduce unnecessary risks.

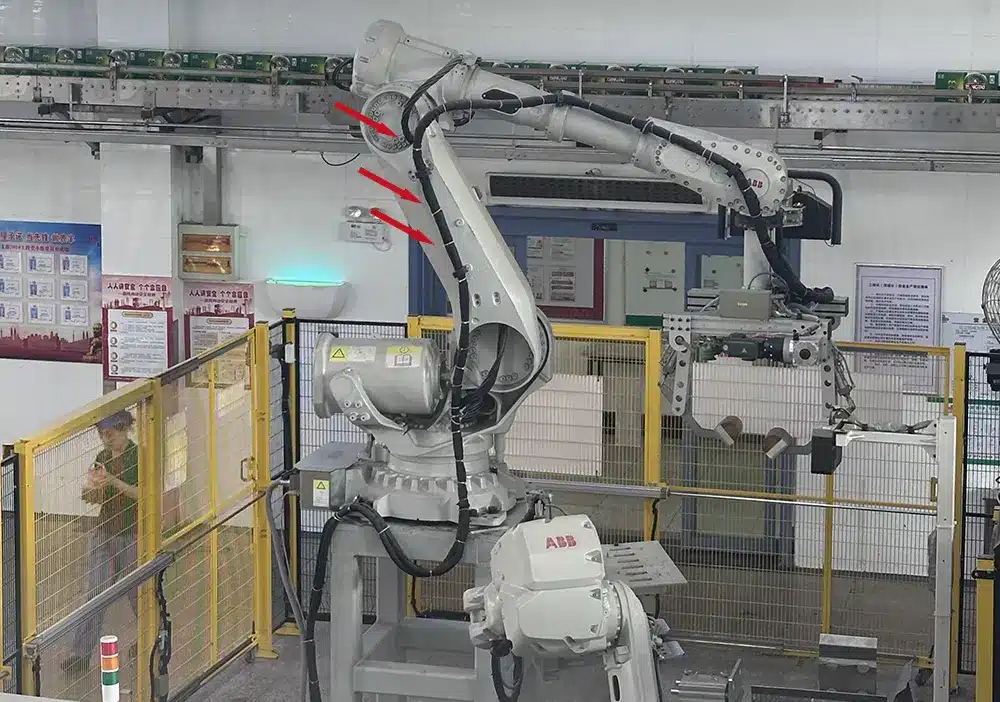

2. Robot wiring

The production line uses ABB industrial robots. Their arms move across a wide range and at high frequency. If cables or air hoses are left loose, they can be pulled or tangled during movement. Cable ties bundle them neatly along joints and brackets, keeping wiring organized and reducing the risk of damage during operation.

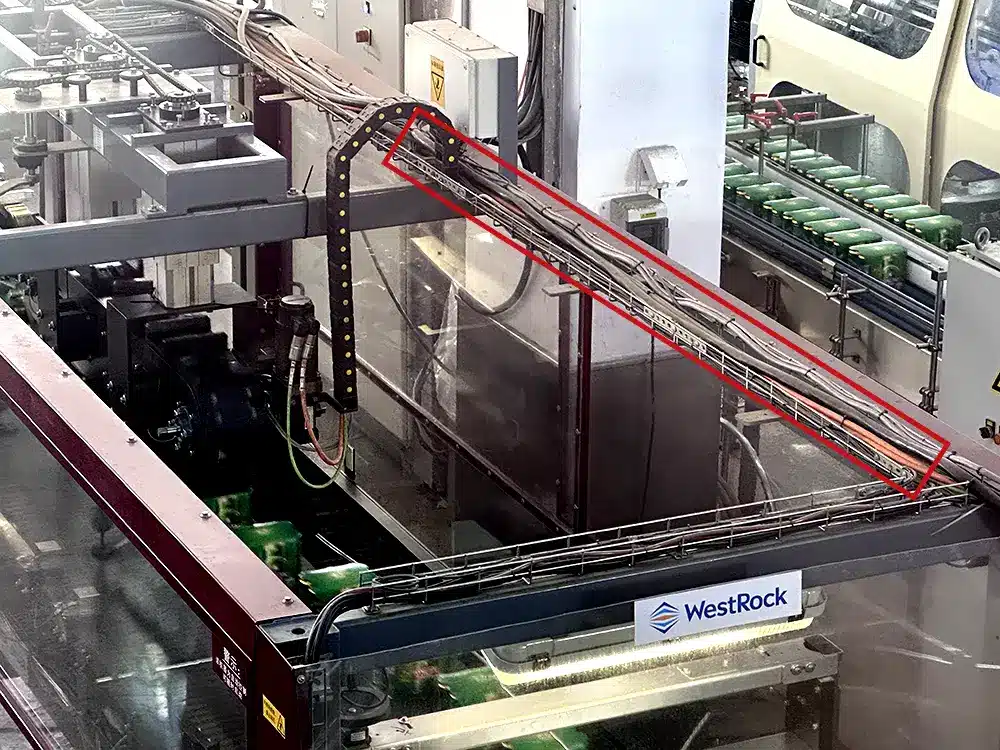

3. Conveyors and sensors

Beer cans move quickly along the conveyor, where many sensors monitor position, speed, and condition. These sensor wires are usually thin and exposed, making them easy to pull and difficult to maintain. By fixing them neatly to the metal frame with cable ties, maintenance becomes easier—technicians only need to cut the ties when replacing or checking the sensors.

4. Coding and inspection stations

At the coding and inspection stations, beer cans pass equipment that prints dates and checks quality. Around the control box and display screen, many cables and air hoses are installed. Cable ties secure them to brackets, preventing shaking and tangling, while keeping wiring orderly. This method not only ensures stable long-term operation but also makes future maintenance more convenient.

Summary

On the automated beer production line shown at the Tsingtao Beer Museum, cable ties play a simple but important role in fixing and organizing cables, indirectly helping automated equipment run smoothly over the long term. Though they are only a small accessory, cable ties have become indispensable on industrial production lines.

Similar uses of cable ties can be seen across many industries. From food and beverage to automotive manufacturing and machinery production, their convenience, reliability, and low cost make them a standard choice in workshops worldwide. Depending on the working environment, buyers can also choose ties with special properties—such as heat-resistant, weather-resistant, or flame-retardant cable tie—to meet more demanding conditions.