The low-temperature test on Nylon Cable Ties is critical for those who need to utilize them in low-temperature environments.

It’s well-known that nylon cable ties often become brittle and prone to breaking in the cold winter months, especially in the frigid, dry regions of the north. To provide more insight into this, our NIKE Plastic Quality Control team specially conducted a low-temperature test on nylon cable ties for you. Our aim is to offer you a preliminary understanding of the performance of nylon cable ties in cold-weather conditions. We hope this initiative gives you a sneak peek into how these cable ties perform when the mercury dips.

Nylon Cable Tie Low-Temperature Test

Test Standards

GB/T 2423.1-2008 (Environmental testing for electric and electronic products – Part 2: Test methods – Test A: Cold)

Type of Test

Ab: Low-temperature test for non-heat-dissipating samples

Test Samples

| Sample description | Material | NIKE Plastic Part No. | Spec. (mm) | Quantity |

| Nylon Cable Tie | PA6 | NK-4.8×200 | 4.8×200 | 20pcs |

| Nylon Cable Tie | PA66 | NK-4.8×200 | 4.8×200 | 20pcs |

| Nylon Cable Tie | Cold-Resistant PA66 | NK-4.8x200C | 4.8×200 | 20pcs |

Testing Process

Let’s break it down into steps:

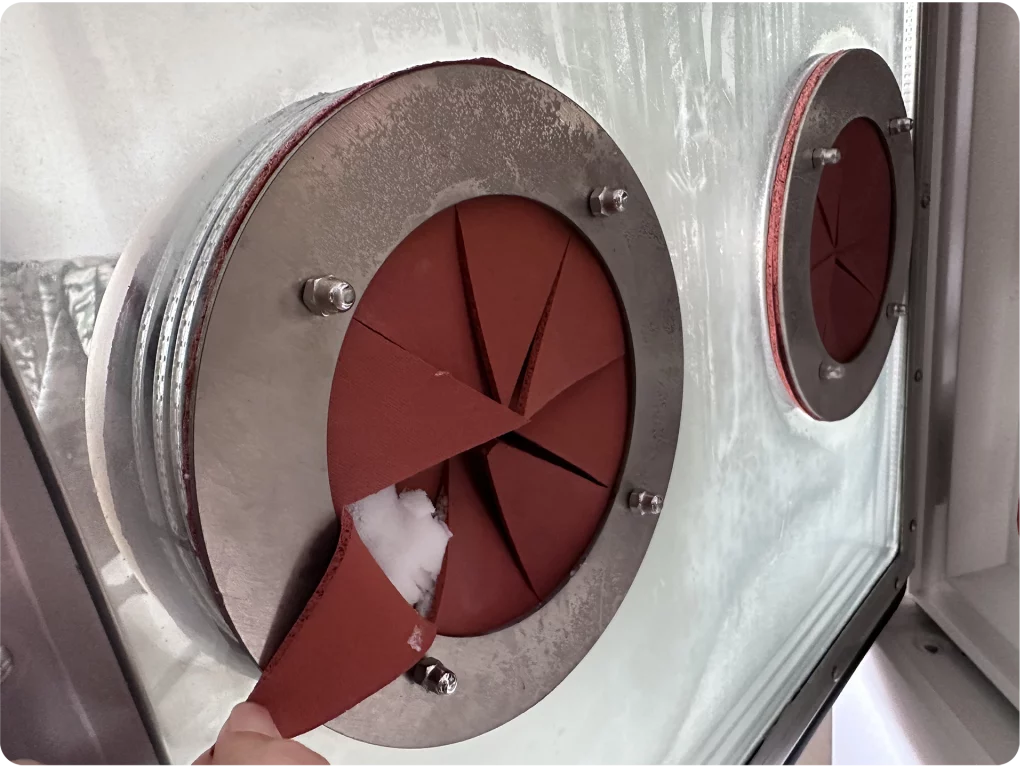

- Place three different types of nylon cable ties into a test chamber at room temperature.

- Gradually lower the temperature inside the chamber until it reaches the extreme level of cold, as dictated by the relevant standards.

- Wait for the temperature of the cable tie samples to stabilize.

- Start the timer and keep this temperature for the set duration as soon as the cable ties reach the desired testing temperature.

PS: NIKE Plastic utilizes a high airflow speed cycle to minimize the time needed for the temperature.

Test Method and Equipment

1. Verification of Test Chamber Performance

Based on the guidelines from GB/T2424.5 and GB/T2424.1, a test chamber with proven qualifications was chosen.

GB/T2424.5: Environmental tests for electric and electronic products. Confirmation of the performance of temperature chambers.

GB/T2424.1: Supporting documentation and guidance.

2. Adjusting the Test Temperature

-40℃。

3. Experiment duration setting

72h。

4. Final Linear Temperature Ramp-up

After the set duration of the experiment has ended, the cable tie samples should be kept inside the test chamber, and then the temperature should be gradually increased to the temperature deviation range within the experimental standard conditions. The temperature variation inside the test chamber should not exceed 1 K/min.

5. Temperature Recovery

The nylon cable tie samples are left to recover under standard environmental conditions. The recovery period should be long enough for the temperature to stabilize, requiring at least one hour.

PS: After the test is complete, take care to avoid water droplets coming into contact with the nylon cable tie samples. This precaution helps to prevent any test variables that could potentially damage the samples.

Test Results

The following are the results of NIKE Plastic’s low-temperature resistance testing on nylon cable ties:

| Sample description | Material | Spec. (mm) | Quantity | -20℃ | -40℃ | ||

| Cracked Samples | Brittle-Break Samples | Cracked Samples | Brittle-Break Samples | ||||

| Nylon Cable Tie | PA6 | 4.8×200 | 20pcs | 0 | 2pcs | 0 | 5pcs |

| Nylon Cable Tie | PA66 | 4.8×200 | 20pcs | 0 | 0 | 0 | 3ps |

| Nylon Cable Tie | Cold-Resistant PA66 | 4.8×200 | 20pcs | 0 | 0 | 0 | 0 |

Results Analysis

In our test, we evaluated the cold resistance of three types of nylon cable ties: Nylon6 (PA6), Nylon66 (PA66), and cold-resistant PA66. We found that the performance of these three materials varied significantly under extremely low temperatures.

In an environment of -40℃, only the cold-resistant PA66 cable ties showed no signs of brittleness and breakage. Thus, this type of cable tie may be the best choice for customers who need to use them in icy conditions.

The performance of PA66 cable ties was the second best. This might be because the molecular chains of PA66 are tighter, and its crystalline structure is more ordered and stable, allowing it to maintain higher strength and toughness at low temperatures.

Finally, the cold resistance performance of PA6 cable ties was the poorest. This might be due to the looser molecular chain structure of PA6 and its relatively weaker crystalline structure, which makes it prone to breakage at low temperatures.

Suggestions

Through our cold-resistant test of nylon cable ties, we observed significant performance differences in various types of nylon cable ties in low-temperature environments.

Firstly, low-temperature-resistant Nylon 66 cable ties demonstrated excellent cold-resistance properties even in extreme -40℃ conditions, without any sign of brittleness or breakage. This suggests that these cable ties are the best choice in cold environments, especially those below -20℃.

Secondly, although the Nylon 66 cable ties did become brittle at -40℃, they still performed better than Nylon 6 cable ties at -20℃. Therefore, considering cost-effectiveness, we suggest that if the environment goes below -10℃ but stays above -20℃, regular Nylon 66 cable ties could be considered.

Finally, we found that the performance of Nylon 6 cable ties in low-temperature conditions is relatively poor. Therefore, we recommend using Nylon 6 cable ties in environments where temperatures stay above -10℃.

Conclusion

Through this low-temperature resistance test for nylon cable ties, we have gained insights into how different materials perform under cold conditions. We hope our findings will assist you in making the most informed choice.

To avoid brittleness, detachment, or cracking of nylon cable ties when used in low-temperature environments, we recommend using specially designed nylon materials for cold applications, such as NIKE Plastic cold weather cable ties.