Some zip ties snap easily—you can break them with just your hands. Others are so tough they can hold up the weight of a grown man without giving in. Why such a big difference?

It all comes down to tensile strength—the measure of how much force a zip tie can take before it breaks. In this guide, we’ll look at the different strength levels of zip ties, what affects their durability, and how to select the right one to ensure your job is done safely and effectively.

1. What Does Tensile Strength Mean for Zip Ties?

Tensile strength is the maximum load a zip tie can hold once it’s locked in place. In other words, after the tie is looped and fastened, how much pulling force can it handle before the locking head or strap gives way?

This rating is typically measured in pounds (lbs) or newtons (N) and indicates the tie’s reliability under stress. A light-duty tie might only manage small cable bundles, while a heavy-duty zip tie can secure large pipes, hoses, or even structural components.

Understanding tensile strength is important because it helps you match the right tie to the right job—too weak, and the tie may fail; strong enough, and it will hold safely for years.

2. Minimum Tensile Strength Standards by Width

The tensile strength of zip ties is generally classified according to strap width. Industry standards specify the minimum loop tensile strength each width must reach:

| Zip Tie Width | Minimum Tensile Strength (N) | Equivalent (lbs) | Typical Applications |

| 2.5mm | ≥ 80N | 18 lbs | Electronics, light cable bundling |

| 3.6mm | ≥ 130N | 30 lbs | Automotive wiring, small hose fixing |

| 4.8mm | ≥ 220N | 50 lbs | Home repairs, electrical installs |

| 7.6mm | ≥ 540N | 120 lbs | Industrial cabling, outdoor use |

| 9.0mm | ≥ 800N | 175 lbs | Construction, HVAC, heavy-duty bundling |

| 12.0mm | ≥ 1100N | 250 lbs | Heavy-duty cables |

These values are standard minimums. High-quality products may exceed them depending on design and material.

3. What Factors Can Affect Zip Tie Strength?

Not all zip ties are equally strong. Several features of the tie itself directly impact its tensile strength:

- Width and thickness: A wider and thicker strap provides more material to resist force, leading to higher minimum strength ratings.

- Material type: Standard nylon 6/6 is common, but modified formulations behave differently. For example, low-temperature resistant nylon keeps flexibility in freezing conditions but usually has lower tensile strength than regular PA66.

- Manufacturing quality: Different injection molding parameters can affect hardness and consistency. High-precision molding helps the tie reliably meet its rated strength, while poor control can make it weaker.

- Tie type: Reusable or releasable zip ties are convenient, but their locking design compromises grip. As a result, their tensile strength is lower than that of standard one-use ties. (See our article: Why Reusable Zip Ties Have Lower Strength Than Standard Ones).

Other external conditions, such as heat, humidity, or UV exposure, can also reduce strength over time, but that’s another topic. For a full breakdown of those factors, see our guide: 9 Factors That Determine the Tensile Strength of Zip Ties.

4. How to Choose the Right Strength Zip Tie?

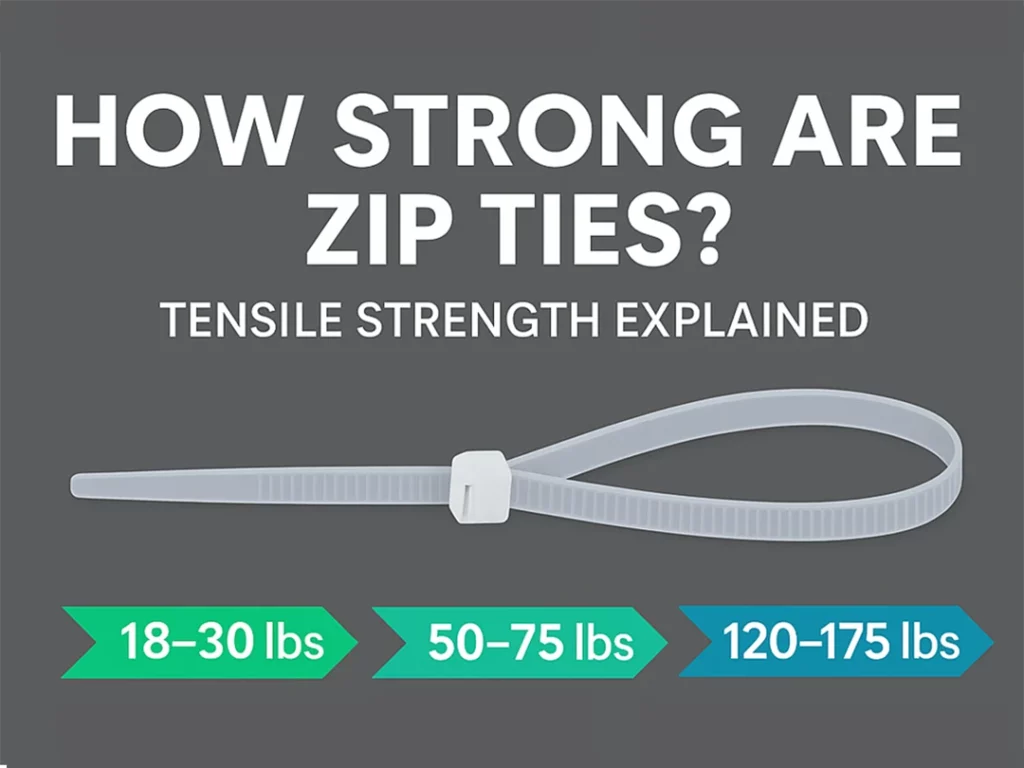

Picking the right zip tie isn’t just about length—it’s about how much load it can safely handle. Here’s a quick guide based on tensile strength ranges:

Household / DIY (18~40lbs): Light-duty ties are enough for organizing small cables, gardening, or general home use.

Automotive / Electrical (50~75lbs): Medium-strength ties work well for securing wiring harnesses, fixing hoses, or managing cables in panels.

Industrial / Construction (120~175lbs): Heavy-duty nylon ties are ideal for larger bundles, conduit fastening, and outdoor installations.

Extreme conditions (>300lbs): For marine, oil & gas, or environments with high heat and chemicals, stainless steel zip ties are the safer choice.

5. FAQs About Zip Tie Strength

Q1: What is the strongest type of zip tie?

Stainless steel zip ties are the strongest, with minimum tensile strengths starting around 1110 N (250 lbs) and going up to 10000N (2248lbs), depending on the size and design.

Q2: Do wider zip ties always mean stronger?

Usually yes. Wider straps have more material to resist force. But material and design also matter—for example, a high-quality 4.8 mm nylon tie can outperform a poorly made 5mm one.

Q3: Do UV-resistant or flame-retardant additives affect strength? Almost no. UV-resistant zip ties utilize additives to block sunlight, and flame-retardant zip ties are formulated to meet fire standards, such as UL94 V0. Both have a minimal impact on tensile strength compared to standard nylon. The main case where strength is noticeably lower is low-temperature nylon ties, which trade some tensile strength for flexibility in freezing conditions.

Q4: Does the color of a zip tie affect its strength?

No. The color itself doesn’t change tensile strength—standard colored zip ties (red, blue, yellow, etc.) perform the same as natural/white ones of the same size and material.

8. Conclusion

Zip ties may look simple, but their strength varies widely—from light-duty ties that hold just 80N (18lbs) to heavy-duty cable ties that can withstand 1100 N (250lbs+).

The key takeaway: choosing the right tensile strength matters more than just choosing the right size. A tie that’s too weak can snap under load, while one with sufficient strength will perform safely and reliably.

Explore our full range of heavy-duty and specialty zip ties to find the right solution for your job.