Cable ties may seem simple, but choosing the right cable tie sizes is crucial for ensuring they fit the task at hand. Whether you’re organizing cables at home, bundling equipment in a workshop, or securing heavy-duty items in an industrial setting, the right size ensures safety and efficiency. This guide breaks down everything you need to know about cable tie sizes in simple terms, making it easy for anyone, even beginners, to choose the right one.

What are Cable Ties

Cable ties, specifically PA66 nylon cable ties, are versatile and durable fasteners designed for bundling and securing items. They feature a flexible strap with serrations on one side and a self-locking head mechanism that ensures a secure hold. The material, PA66 nylon, offers excellent mechanical strength, flexibility, and resistance to environmental factors like temperature changes and UV exposure.

Cable ties come in a wide range of sizes, from small ties for light-duty tasks to heavy-duty options for industrial use. Their sizes are defined by length, width, and tensile strength, each tailored for specific bundling needs. Understanding the significance of size is essential for selecting the most suitable cable tie sizes for your application.

Understanding Cable Tie Sizes

Definition of Sizes

Cable tie sizes involve multiple dimensions, each impacting the tie’s strength and usage. Here are the primary sizes components:

1. Length:

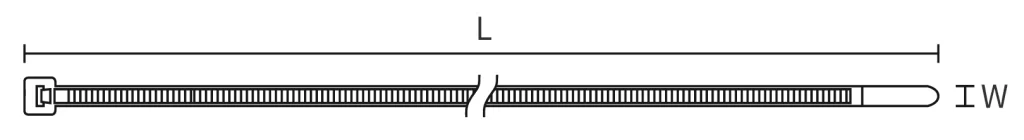

Length: The length of a cable tie generally refers to the measurement from end to end, including the tail and head.

Effective Length: This is the usable length of the cable tie, it refers to the distance from the locking head to the final section of serrations at the end of the tie, as shown in the diagram below. When selecting cable ties, considering the effective length is essential to ensure the cable tie fits your bundle size perfectly without being too long or too short.

2. Width:

The width influences the tie’s strength and durability. Wider ties generally have a higher tensile strength, making them more suitable for heavy-duty applications. Narrow ties, on the other hand, are suited to lighter tasks where flexibility and a lower profile are more critical.

3. Thickness:

Thickness refers to the measurement of the cable tie’s body, specifically in the middle section, as slight variations can occur along different points of the tie. This dimension plays a critical role in determining the tie’s strength and flexibility. While thicker ties generally provide greater durability, they may also be less flexible and will be a bit more challenging to operate. Choosing the suitable thickness requires balancing strength, flexibility, and ease of use, rather than just opting for the thickest tie available.

4. Maximum Bundle Diameter:

This refers to the largest diameter of the cable or bundles the tie can secure. It’s based on the effective length of the tie. Since the Dmax=π/Effective Length

How to Choose the Right Cable Tie Sizes

1. Length

Measure the Bundle Size: Start by measuring the diameter of your bundle. This helps you figure out the minimum length you’ll need to wrap the tie securely around it.

Allow for Extra Length: Pick a tie that’s slightly longer than the bundle size. This gives you some room to handle and operate.

2. Width

Consider Tensile Strength Needs: The width of a cable tie determines its strength. Wider cable ties generally provide higher tensile strength, making them suitable for heavy-duty tasks, while narrower ties are ideal for lighter jobs.

Here are the tensile strength standards corresponding to different cable tie widths for reference.

Examples of Cable Tie Sizes Selection

Selecting the right cable tie sizes can greatly improve task efficiency. Here are some practical examples:

Example 1: Home Cable Management

- Scenario: Organizing cables behind a TV or computer.

- Recommended Size: For household cable organization, smaller cable ties, around 4-6 inches (100-150mm) in length and 2.5-3.5mm in width, are typically sufficient.

- Reasoning: These ties are manageable in smaller spaces and provide enough strength to keep cables neat without adding bulk.

Example 2: Outdoor Gardening

- Scenario: Securing plants to stakes or bundling garden hoses.

- Recommended Size: For outdoor gardening, medium cable ties around 8-10 inches (200-250mm) in length and about 4.8mm in width are ideal.

- Reasoning: Medium-sized ties provide a secure hold on plant stems or garden equipment, without damaging delicate plants. Additionally, UV-resistant options are preferable for long-lasting use outdoors.

Example 3: Large Cable Bundling (Industrial Use)

- Scenario: Bundling large cables or hoses in a warehouse or industrial setting.

- Recommended Size: For heavy-duty bundling, 12-inch (300mm) or longer cable ties with a width of 12mm are ideal.

- Reasoning: Wider, longer ties offer high tensile strength, making them suitable for heavy-duty bundling. They ensure a tight, secure hold even on large or heavy items, which helps maintain organization and safety in industrial environments.

Cable Tie Sizes Chart

Here’s a quick guide to help you pick the appropriate cable tie sizes for any task. This table includes typical lengths, widths, and the minimum tensile strengths for your choosing.

| NK NO. | Length | Width | Max.Bundle DIA.(mm) | Tension | ||

| Inch | mm | (mm) | lbs | kgs | ||

| NK-3×80 | 3 3/16” | 80 | 2.4 | 16 | 18 | 8 |

| NK-3×100 | 4‘’ | 100 | 2.4 | 22 | 18 | 8 |

| NK-3×120 | 4 3/4” | 120 | 2.4 | 30 | 18 | 8 |

| NK-3×150 | 6” | 150 | 2.5 | 35 | 18 | 8 |

| NK-3×160 | 6 1/4” | 160 | 2.5 | 40 | 18 | 8 |

| NK-3×200 | 8” | 200 | 2.4 | 50 | 18 | 8 |

| NK-4×100 | 4” | 100 | 3.6 | 22 | 40 | 18 |

| NK-4×120 | 4 3/4” | 120 | 3.6 | 30 | 40 | 18 |

| NK-4×150 | 6” | 150 | 3.6 | 35 | 40 | 18 |

| NK-4×180 | 7” | 180 | 3.6 | 42 | 40 | 18 |

| NK-4×200 | 8” | 200 | 3.4 | 50 | 40 | 18 |

| NK-4×250 | 10” | 250 | 3.4 | 65 | 40 | 18 |

| NK-4×300 | 11 5/8” | 300 | 3.6 | 80 | 40 | 18 |

| NK-4×370 | 14 1/2” | 370 | 3.5 | 102 | 40 | 18 |

| NK-5×120 | 4 3/4” | 120 | 4.8 | 24 | 50 | 22 |

| NK-5×150 | 6” | 150 | 4.8 | 35 | 50 | 22 |

| NK-5×180 | 7” | 180 | 4.8 | 42 | 50 | 22 |

| NK-5×200 | 8” | 200 | 4.8 | 50 | 50 | 22 |

| NK-5×250 | 10” | 250 | 4.8 | 65 | 50 | 22 |

| NK-5×280 | 11” | 280 | 4.8 | 70 | 50 | 22 |

| NK-5×300 | 11 5/8” | 300 | 4.8 | 82 | 50 | 22 |

| NK-5×350 | 13 3/4” | 350 | 4.8 | 90 | 50 | 22 |

| NK-5×360 | 14” | 360 | 4.8 | 95 | 50 | 22 |

| NK-5×370 | 15” | 370 | 4.8 | 102 | 50 | 22 |

| NK-5×400 | 15 3/4” | 400 | 4.8 | 105 | 50 | 22 |

| NK-5×430 | 17” | 430 | 4.8 | 115 | 50 | 22 |

| NK-5×450 | 17 3/4” | 450 | 4.8 | 130 | 50 | 22 |

| NK-5×500 | 19 11/16” | 500 | 4.8 | 150 | 50 | 22 |

| NK-5×550 | 22 10/16” | 550 | 4.8 | 175 | 50 | 22 |

| NK-5×600 | 6” | 600 | 4.8 | 33 | 50 | 22 |

| NK-5×650 | 25 19⁄32” | 650 | 4.8 | 42 | 50 | 22 |

| NK-8×250 | 10” | 250 | 7.6 | 63 | 120 | 55 |

| NK-8×300 | 11 5/8” | 300 | 7.6 | 82 | 120 | 55 |

| NK-8×350 | 13 3/4” | 350 | 7.6 | 90 | 120 | 55 |

| NK-8×370 | 15” | 370 | 7.6 | 98 | 120 | 55 |

| NK-8×400 | 15 3/4” | 400 | 7.6 | 105 | 120 | 55 |

| NK-8×450 | 17 3/4” | 450 | 7.6 | 118 | 120 | 55 |

| NK-8×500 | 19 11/16” | 500 | 7.6 | 150 | 120 | 55 |

| NK-8×550 | 22 10/16” | 550 | 7.6 | 165 | 120 | 55 |

| NK-8×600 | 6” | 600 | 7.6 | 170 | 120 | 55 |

| NK-8×650 | 25 19/32” | 650 | 7.6 | 190 | 120 | 55 |

| NK-8×720 | 27 1/2” | 720 | 7.8 | 210 | 120 | 55 |

| NK-8×760 | 29 1/2” | 760 | 7.6 | 220 | 120 | 55 |

| NK-10×400 | 15 3/4” | 400 | 9 | 105 | 175 | 80 |

| NK-10×450 | 17 3/4” | 450 | 9 | 125 | 175 | 80 |

| NK-10×500 | 19 11/16” | 500 | 9 | 145 | 175 | 80 |

| NK-10×550 | 22 10/16” | 550 | 9 | 165 | 175 | 80 |

| NK-10×600 | 6” | 600 | 9 | 175 | 175 | 80 |

| NK-10×650 | 25 19⁄32” | 650 | 9 | 190 | 175 | 80 |

| NK-10×720 | 27 1/2” | 720 | 9 | 210 | 175 | 80 |

| NK-10×760 | 29 1/2” | 760 | 8.8 | 220 | 175 | 80 |

| NK-10×800 | 31 1/2” | 800 | 8.8 | 225 | 175 | 80 |

| NK-10×920 | 36 7/32” | 920 | 9 | 265 | 175 | 80 |

| NK-10×1020 | 40 5/32” | 1020 | 9 | 295 | 175 | 80 |

| NK-10×1200 | 47 1/4” | 1200 | 9 | 320 | 175 | 80 |

| NK-10×1300 | 51 3/16” | 1300 | 9 | 330 | 175 | 80 |

| NK-10×1500 | 59 1/16” | 1500 | 9 | 460 | 175 | 80 |

| NK-12×300 | 11 5/8” | 300 | 12 | 80 | 200 | 91 |

| NK-12×400 | 15 3/4” | 400 | 12 | 105 | 200 | 91 |

| NK-12×500 | 19 11/16” | 500 | 12 | 150 | 200 | 91 |

| NK-12×600 | 6” | 600 | 12 | 175 | 200 | 91 |

| NK-12×650 | 25 19⁄32” | 650 | 12 | 190 | 200 | 91 |

| NK-12×750 | 29 17/32” | 750 | 12 | 220 | 200 | 91 |

| NK-12×800 | 31 1/2” | 800 | 12 | 225 | 200 | 91 |

Conclusion

Choosing the suitable cable tie sizes might seem simple, but it’s key to getting the job done securely and efficiently. This guide aims to make choosing cable ties straightforward, offering practical advice for anyone from beginners to seasoned professionals. By picking the right size, you’ll ensure that your project stays secure and organized, making the job smoother and more reliable.